Adoption of digital technologies in chemical manufacturing will lead to significant reduction in the overall cost and waste generation besides energy optimization, productivity, and yield improvement

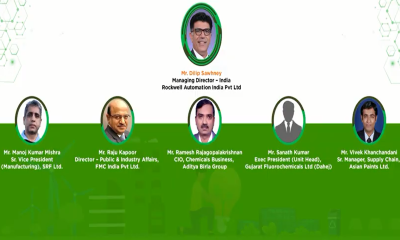

“There are large chemical industries handling hazardous processes wherein safety, quality, cost and delivery are the key drivers. With the fast changing global dynamics, the industries have the need to go digital and add new technologies. There are many digital technologies available which can change how we work. If these technologies are applied rightly, one can bring a significant change in the processes. A lot of data can be generated, stored, and analyzed in a faster mode. So digital technology defines tools, automated systems, technology devices, and resources that generate processes that store various information," says Manoj Kumar Mishra, Senior Vice President (Manufacturing), SRF Limited.

Companies like us are looking at manufacturing effectively, efficiently, safely and adequately. There are three aspects to it and that includes performance, productivity and flexibility. That touches upon huge reorganization of supply chain and mass customization. With all this, technology has to make our life simpler, faster and comfortable. We have implemented technologies such as Artificial Intelligence at SRF. For example, if there are thousands of cans being filled in with chemicals and one can miss it, the AI driven camera can alert and stop the process to help rectify the error. The other thing is that if you are manufacturing a byproduct and you need to analyze, it will be dangerous to send a person to do so physically. AI helps in gathering data on patterns and analyzing it to create models. Cloud computing is another technology that has been significantly applied to make the process stable and you can access the data anytime, anywhere. During the pandemic, it actually helped us to manage the plant remotely," comments Mishra.

Mishra was speaking at the session on 'Digital Transformation: Reinventing Chemical Manufacturing' at 3rd edition of Sustainability Conclave 2021: Clean India & Green India organized by Indian Chemical Council (ICC).

"From basics to advanced control, digitization has changed a lot in the chemical industry. Nobody talks about RoI from digital anymore due to the acceptability it has gained. The processes are getting controlled right from design and a lot of things are customized and factored into it. But when you go into operation and you have this lot of cross control automation that really helps you to find out the fine tuning of parameters. These are high stream generations, opening of valves, whether you are using the turbines in full capacity, whether you are able to use the cooling water systems effectively. These are the things in the background we can control. We use them for energy optimization. Sustainability is here to stay and it has to be adopted. The company management which doesn't understand the significance must look at the integration of platforms in totality. The digital twins and computational models to predict the properties of chemicals to be produced will make the difference. Database and fundamental base models are driving it in many applications. We have used it in many industries. The simple applications such as tanker loading etc. can be simplified due to such technologies,” says Sanath Kumar, Executive President (Unit Head), Gujarat Fluorochemicals Limited - Dahej.

"With the kind of risk we pose to both internal and external stakeholders, the onus lies on us to go beyond six sigma. Nobody expects us to have any loopholes just like the aircraft industry. We can't achieve that manually; the way we have been doing so far. What we have seen through various accidents in India and China is the adoption of digital from manual, be it people movement, draining, track and trace devices. From a single control point we were able to have a broad look on what's happening to people and process. At each stage, we put up warning signals in the form of red flags which go up every time one sees any deviation at any level. Similarly, the security area also is a big concern and as an example today our plant at Panoli can be viewed by anybody from Philadelphia, especially in light of the geo-political law and order situation. Our plants have become quite vulnerable especially in the hazardous chemical situation. Creating electronic surveillance beyond physical surveillance has become mandatory. The integration of all these aspects all in one remotely can bring a sea change. We have a seven-year record of zero accidents or incidents at Panoli,” says Raju Kapoor, Director – Public & Industry Affairs, FMC India.

“The potential of digital technologies in reducing manufacturing cost is very well acknowledged. The level of data which we were able to collect, store and analyze has given us a clear understanding of the process right now. From that only follows how we can better control and optimize. The level of clarity we were able to get on how to better the performance was only possible with the level of technologies available with us. So from that perspective, the reduction in manufacturing cost is very well established. There are various technologies such as AI-IoT, software analytical platforms available to us to do this. When it comes to return on investment (RoI), there are four key aspects that drive the digital transformation i.e. technology, data, process, and people. Very often we tend to focus only on the technology part. That is where we seem to miss our ROI objectives. We should rather spend equal amounts of time on data processes and people also. For the data it is very important to make sure we have the ownership defined so as to get the data quality is there. We should start with an end to end process in mind instead of doing QC pilots here and there, covering some parts of the process. Without realizing its true potential, it will never help us to achieve our goals," says Ramesh Rajagopalakrishnan, CIO - Chemicals Business, Aditya Birla Group.

“From a sustainability point of view, advanced analytics is drastically helping us due to its ease of use, cost effectiveness, and productivity. The amount of data you gather and then analyze, based on which you are able to optimize the operations and realize the capacities including the remote efficiency. Through all of these, you are able to reduce the energy consumption. It helps our partners to reduce their Scope 3 emissions, Due to the ease of use, we were able to measure at the lowest scale. Earlier it was just macro measurements, now we have pointed data. Technology makes it easier in terms of safety. There is real time monitoring due to IoT, safety and electrical safety. A lot of solutions that can be easily implemented. RoI is good in both areas. Packaging industry too is taking up technology. It helps us to identify the opportunities. If we look at plastics downstream, this was a huge problem for both now chemicals but globally. Technology is helping us to make it linear,” says Vivek Khanchandani, Senior Manager - Supply Chain, Asian Paints.

"Even though the chemical industry has been practicing sustainability for a long time now, the focus on such initiatives have clearly seen a step change in terms of the management and stakeholder focus in the last half a decade. The initiatives that have witnessed focused activity in the areas such as energy optimization, waste reduction, productivity and yield improvement. We are now talking about circular economy, zero emissions, green chemistry and the list goes on. On one hand you have government norms and on the other hand you have social responsibilities and environmental concerns. Undoubtedly there is also an element of increasing energy cost. They are all kind of pointing in the same direction and that is to remain more sustainable during the conduct of operations from an industry perspective," says Dilip Sawhney, Managing Director – India, Rockwell Automation India.

Another thing that is happening at the same time is advancement in configurationally powered and digitization solutions that are available now and were never before there. A cross section of industry, therefore, are now exploring or deploying these new age solutions to derive much more benefits around these themes that I spoke about. These solutions have the capability to derive significantly higher levels of performance, leveraging use case technologies, KPI dashboards, and machine learning are increasingly being implemented in discrete industries in batch and continuous processes with predictive maintenance and control. All of this is beginning to happen at a pace that far exceeds what we thought was possible just a few years ago. That is the power of Industry 4.0 where the growth is getting accelerated by leveraging the technology," adds Sawhney.

Subscribe to our newsletter & stay updated.