Digital transformation within chemical industry not possible without right culture

With increasing complexity due to a variety of products and processes, the chemical industry aims to adopt digital technologies for faster outcomes. By using data to drive business and operational decisions, many companies are progressing with their own transformation to the next level of performance and operational excellence.

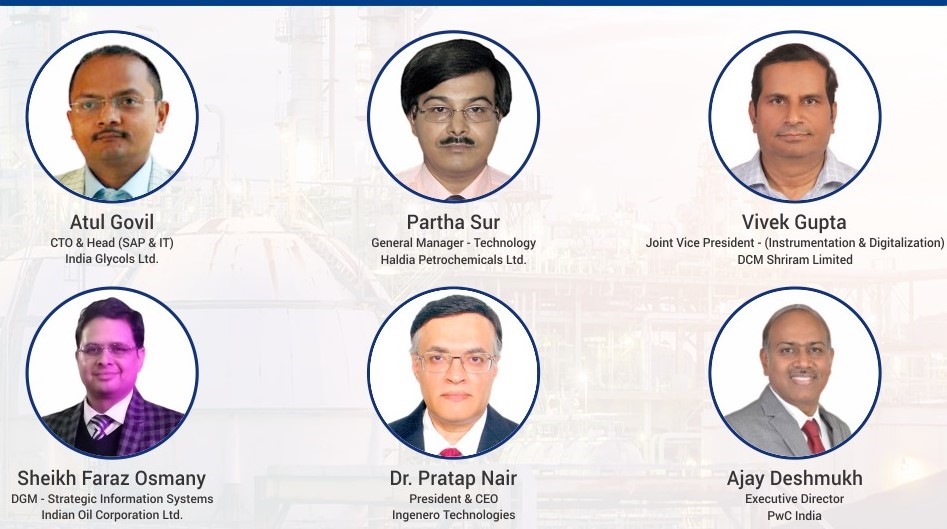

Leading experts from the chemical industry shared their insights on the adoption of digital technologies to increase productivity at the ‘NextGen Chemicals & Petrochemicals Summit 2022’ organized by Indian Chemical News on July 21, 2022. The panel discussion themed, ‘Digitalization: Holistic Approach Need of the Hour’ was moderated by Ajay Deshmukh, Executive Director, PwC.

“Visibility around operations is very important as in most of the organizations there are systems such as SAP, ORACLE or others which are transactional systems that capture data in a retrospective manner. Then we have analytical systems that come into picture but by the time analytical output comes out, it is too late. Having the right skilled personnel is another big challenge. There is an immediate contingent need to capture the wisdom of the retiring workers and automate the knowledge to the extent possible,” said Atul Govil, CTO &Head (SAP & IT), India Glycol Limited.

“Not everything can get replaced with AI-ML but much of the analytics which is being done on a daily basis can be automated. We have a control tower where we can monitor the entire process, real time tracking of KPIs. We have used RFID to track material, manpower and vehicular movement. We are working on geo- fencing for loading and unloading of material. We have to systematize the entire process which would help in the reduction of cost,” added Govil.

Partha Sur, General Manager-Technology, Haldi Petrochemicals Limited believes that the mindset of the leadership is very important for the adoption of digital technologies.

“Having a composition of employees in different age and experience brackets, you tend to experience difficulties at the initial stage. However, the right strategies matching the expectations could help in better implementation. Earlier when we used to run a traditional business and wanted to go for transformation, there were a lot of investment requirements and questions were asked on how it would help. Though there was ERP and other systems in place, there were a few missing links. DCS vendors wouldn’t allow access to the database. We took a holistic view and created a basic infrastructure for the data pull out. The younger generation became the game changers and helped to bring in new changes, The workshop helped and a lot of new ideas came in. Covid times gave impetus to the digital tools model by model, from lower to higher levels,” said Sur.

“Bringing in visibility into process operations is very difficult. Keeping different aspects in mind, we started bringing in KPIs, and reports on one platform. We built the basic infrastructure such as KPIs dashboard, etc. and moved from just manufacturing to other external operations, be it safety or process led digital interventions. From production level to the EBITDA level, it took almost three years to reach there,” Sur added further.

“DCM Shriram’s Kota complex is 55 years old. We have a legacy of updating and upgrading our infrastructure from time to time. It took time for us to bring the right kind of mindset and culture of innovation to break the digital barrier. We started our digital journey with forming a cross functional group of electrical, process, mechanical and instrumentation. We decided to make investments only to address the problem areas rather than having a dashboard just to experiment,” said Vivek Gupta, Joint Vice President- (Instrumentation & Digitalization), DCM Shriram Limited.

“The legacy equipment such as compressors that were 50 years old and vibration, temperature were not available on Differential Scanning Calorimetry (DSC). Pre-defined internal monitoring was a norm those days and to begin with we started measuring vibrations on all critical equipment. The first concept was to isolate whatever measurements we are taking on AI sensors and give it on mobile and laptop. The right information at the right time to the right person helped in controlling the damage to the instruments. Now a single sensor with six measurements can help in Technology if used in the right way can help a lot,” added Gupta.

“Indian Oil has a 15,000 kilometre pipeline network and 50,000 marketing touch points at end customer level. To create digitalization at such a level is not an easy task. Management has a very important role to play and if you don’t have the backing, nothing moves. Since it requires investment and attention at all levels, senior management will have its” mentioned Sheikh Faraz Osmany, DGM- Strategic Information Systems, Indian Oil Corporation Limited.

Providing details on the company’s digital roadmap, Osmany added: “We started our digital journey in 2017 when we started identifying the gaps. We have been at the forefront of implementing the best technologies. We then formed a strategic information system, iDrive, the digitalization project of Indian oil. AI-ML for the sake of it is not good. We need to understand the business process and domain knowledge and build the mother around a used case. We moved on from preventive maintenance to conditioned maintenance, primarily We took some time to build the data around We have had change management workshops at all levels and most of the initiatives have been successful. Digitalization at a broader level is a gradual process and doesn’t happen quickly.”

“In the process industry, there is an abundance of data available to us in the last 2-3 decades. Only 10% of this data is actually utilized. Today computing, storage and a whole lot of digital technologies are enabling us to utilize this data in a better way. However, to further use these technologies, there are very specialized engineering aspects such as data engineering, precision engineering, analytics, ultimately leading us to augmented intelligence to give data driven actions helping into productivity, sustainability and so on. I call it AppliedAI,” said Dr Pratap Nair, President & CEO, Ingenero Technologies.

“Over the period of five years, we have implemented many solutions for refiners, petrochemical plants and industries. There are plethora of technologies that could help in simplifying the processes. One such solution is Decision Excellence Engineering Process (DEEP), a specialized Applied AI engineering around advanced analytics. From identifying and defining the problem to creating solutions through augmented intelligent dashboard, technology synthesis and application focus is critical for successful Applied AI applications,” added Dr Nair.

The NextGen Chemicals Petrochemicals Summit 2022 was supported by the leading names of the industry. The platinum partner was Elliot Group.Regulatory Knowledge Partner was GPC. Gold partners of the event included Ingenero, Premier Tech, Carbanio and Deepak Nitrite. Among the associate partners were PIP and Huntsman. The industry partners of the event included AMAI, Croplife India, and ACFI.

Subscribe to our newsletter & stay updated.