Dr. Pratap Nair of Ingenero Technologies explains the relevance of extracting action oriented Augmented Intelligence from data

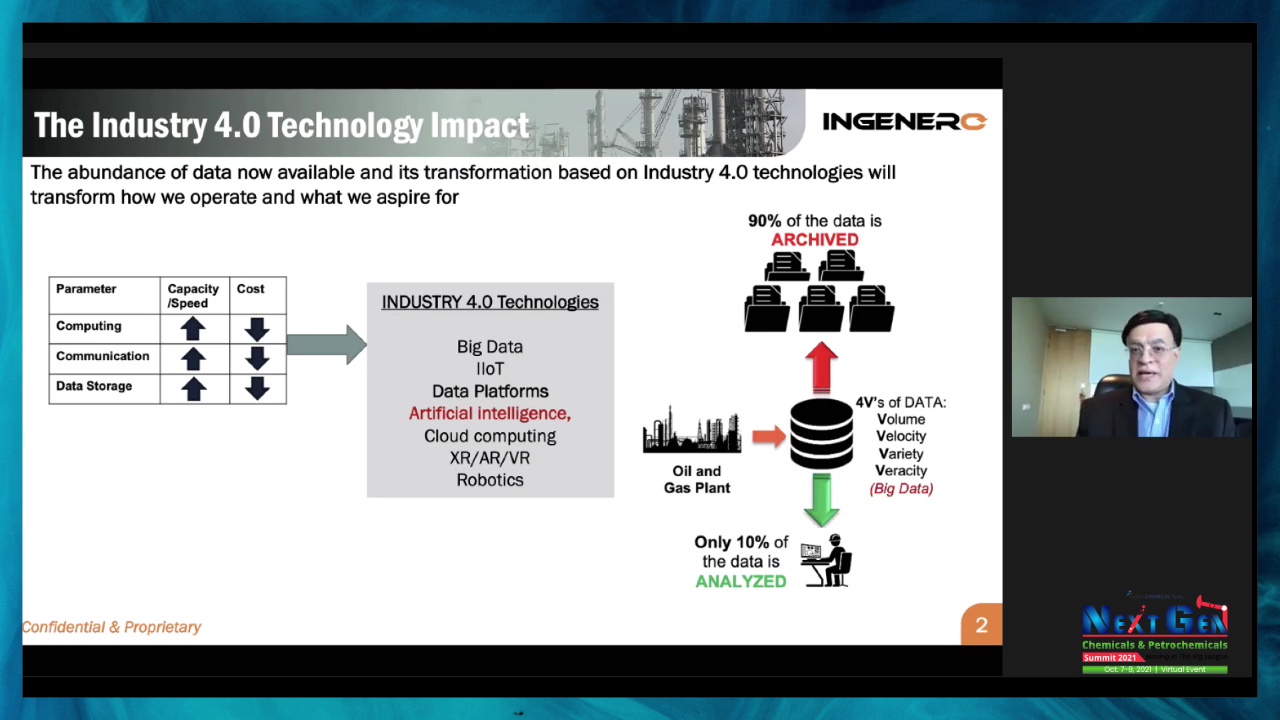

Industry has no dearth of data but only 10 percent of this data is being actually utilized and about 90 percent is being archived. This is truly big data we have got. Over the past decade or so there has been a tremendous improvement in computing speeds, communications, and capacity of storage, all at a much reduced cost. And it has driven the industry to what we called Industry 4.0 technologies which have made a lot of these possible. These include Artificial Intelligence (AI), Big Data, Cloud Computing and so on. What it enables us to do is be able to use the 90 percent of that data which is traditionally just archived and convert that into augmented intelligence,” says Dr. Pratap Nair, President and CEO, Ingenero Technologies.

Dr. Nair shared his presentation titled, ‘Extracting action oriented Augmented Intelligence from data – A key pillar for sustainable improvement through Digitalization’ at the NextGen Chemicals & Petrochemicals Summit 2021 organized by Indian Chemical News on 7-8 October, 2021.

“Analytics driven decisions including increased productivity, environmentally driven sustainability is really the result of such Industry 4.0 technologies. Ingenero technologies offers I-SSPDE, an augmented intelligence solution which is a digitally connected, automated, adaptive advanced data analytics solution that makes data useful. It is an essential tool to achieve digitalization goals in process manufacturing. It uses data from various sources to help operators and engineers in making decisions. It has been successfully used in petrochemicals, crude oil plants, midstream oil and gas, and specialty chemicals plants,” adds Dr. Nair.

Speaking about the technology, Dr. Nair says, “AI is often referred to as being synonymous with Machine Learning (ML) which of course has added a huge value to it in the past few years. However, we need to understand the difference between the two. While ML is the science of getting computers to act in real time situations besides allowing systems to automatically learn from previous experiences, the AI has deep learning models. There is a deep domain knowledge and first principle models have been developed after several years of on the ground experience in chemical engineering. Combining the both areas gives us a composite AI and that is what is really required in our industry.”

“Being able to seamlessly weave together the various technologies that are needed. It is really about the handling of data, whether it is the cloud computing, data platforms, connectors and so on. Taking the data, storing it, doing initial processing and making it available for applications like advanced analytics which is the AI model, digital twins, hybrid models that are coming into play and then of course the results coming out of analytics has to be presented in a form that is easily interpretable and usable. Global brain access to allow resources sitting globally to have access to any of these applications. What this provides at the end of the day is the decision quality insights.”

Subscribe to our newsletter & stay updated.