Combination of thermally conductive plastics with metallic cooling elements in hybrid technology

LANXESS, one of the leading suppliers of thermoplastic high-performance polymers, has developed a new concept for radar sensors with integrated thermal management that will benefit autonomous driving.

Though there is still a long way to go, driver assistance systems are increasingly set to become a key feature of future generations of cars. 360-degree monitoring of the vehicle’s surroundings is enabled by – among other things – radar waves. The radar sensors are an essential component of, for example, distance control, lane change monitoring, collision avoidance and blind spot monitoring systems.

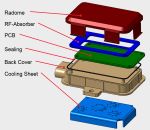

The sensors have to be dust- and water-proof and so are designed as fully enclosed systems. But this makes it difficult for heat to be effectively dissipated from the inside, which, in turn, can impair the performance of the electronics and durability of the sensors.

“This is why we developed a concept that allows heat to be dissipated by means of thermally conductive plastics in combination with metallic cooling elements,” says Gregor Jaschkewitz, Application Developer in the High Performance Materials (HPM) business unit at LANXESS. “The individual sensor components are assembled using integrated snap fits and hot rivets, a process that is much less costly and time-consuming than using screws.”

LANXESS believes that sensors for driver assistance systems will offer a wealth of opportunities for its Durethan polyamides and Pocan polyesters. “We want to benefit from the huge growth potential in this application segment and advance technological innovation with our own ideas – like the concept for radar sensors,” says Dr. Christopher Hoefs, a global application development expert in HPM. For example, the business unit also recently unveiled a concept for the modular design of charging connections for electric vehicles.

HPM has pooled its extensive knowhow in material, application, process and technology development under the HiAnt brand in order to support partners and customers in projects. Hoefs stresses: “We are supporting our partners at all stages of application development – from concept design, material optimization and mechanical and rheological simulation through to component testing and the start of series production.”

Subscribe to our newsletter & stay updated.