Technology, demand generation, infrastructure and affordability are critical for the success of hydrogen. Cost of electrolysers has to be brought down, reducing supply chain cost, and creating end users are key drivers

With the growth in concern of climate change and global warming, hydrogen is being looked at as the fuel of the future. The major driving factors responsible for the growth of the hydrogen market is the surge in its demand in the end-user industry. Furthermore, use of hydrogen in power generation and stringent environmental regulations towards cleaner forms of energy have fueled the market growth. However, high transportation and storage cost of hydrogen and stagnant pricing of hydrogen hampers the market growth.

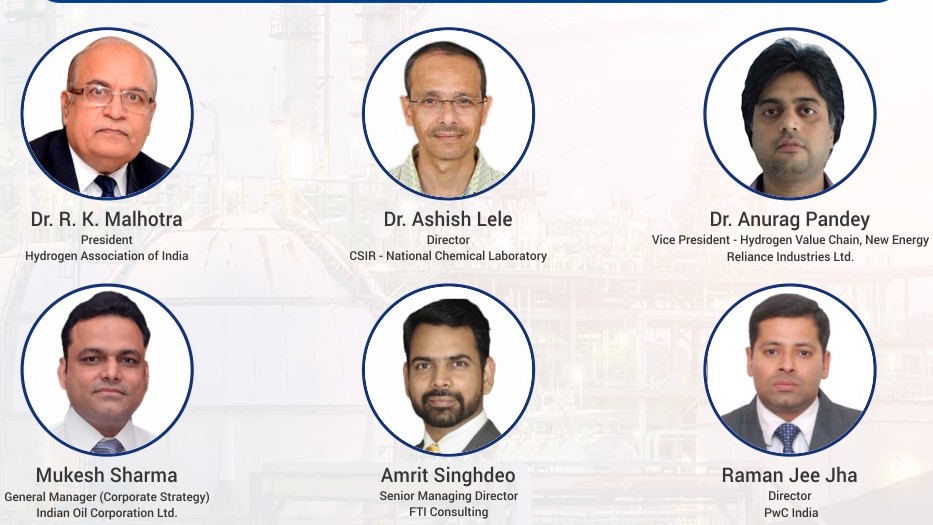

“We must talk about overall hydrogen economy irrespective of colors and not just only promote green hydrogen,” said Dr R K Malhotra, President, Hydrogen Association of India.

Dr Malhotra added further: “If we only talk about green hydrogen we will be waiting for its cost to come down which will be at least a decade away if not more. If we talk about hydrogen economy and India as an exporting hub of hydrogen, the power generation in India by 2026 is estimated to be 620 gigawatt, out of which 38% will come from coal, and 44% from renewables. As per Central Electricity Authority estimates, 870 gigawatt of electricity will be required by 2030. Even if we achieve 500 gigawatt of renewable electricity, we will need 35% from fossil fuels. If we continue to use fossil fuel based electricity for green power we should ask whether we should be doing that? If we have to become a hydrogen hub by 2030, we have to allow all colors of hydrogen. Otherwise we will miss out on the infrastructure for hydrogen. We should support PLI for electrolysis but we can’t ignore the need for infrastructure. Technology, demand generation, infrastructure and affordability are critical for the success of hydrogen.”

Dr Malhotra was speaking along with other leading industry stakeholders on the current scenario in the Indian hydrogen market at the ‘NextGen Chemicals & Petrochemicals Summit 2022’ organized by Indian Chemical News on July 21, 2022. The panel discussion themed, ‘Hydrogen: The Game Changer’ was moderated by Raman Jee Jha, Director, PwC India.

“If you don’t create a demand for green hydrogen, there will be no investment in the market. Right now there is no demand for hydrogen, especially green hydrogen because technology hasn’t really matured,” said Mukesh Kumar Sharma, General Manager (Corporate Strategy), Indian Oil Corporation Limited.

“A lot of efforts are going on to reduce the cost and rightly so the ecosystem has to be created because nobody is going to invest in the costly technology. If you have to decarbonize, you have to either tax the carbon and then only people will come or some policies from the government to reduce the carbon emission by at least 10%. If we look at Europe, they are putting up the right policies and investing big time into green initiatives such as biofuels and solar energy. Similar push has to be given to hydrogen as without initial demand, there will be no R&D and no major technological advancements. To scale up the investment and improvement in technology followed by manufacturing as it will be cheaper. Indian Oil and L& T have partnered for manufacturing electrolyzers in India. Push in terms of the PLI scheme and other policies are important,” added Sharma.

“We are in the infancy of the hydrogen economy. While hydrogen has been used in the industry for decades, the kind of hydrogen we are talking about has different uses, right from mobility to electricity generation which will require a lot of elements of the hydrogen economy to come together and prove that hydrogen is really a vibrant energy vector for large economies,” said Dr Anurag Pandey, Vice President, Hydrogen Value Chain, New Energy, Reliance Industries Limited.

“As an industry our job is bringing the best technology together, building infrastructure for smaller projects to bring the ecosystem together but ultimately you have to expand to the large scale at par with fossil fuels to achieve the cost targets to replace the existing energy vectors. Based on the green energy, there are a few things that we need to learn and prove on the ground. Starting from hydrogen production which obviously comes first but I would say looking at renewable electricity, using electricity to generate electricity is one case but using electricity to produce green hydrogen is another because that has an impact on supply chain management. Making the various elements of the value chain cost effective vis a vis existing energy vectors. Cost of electrolysers has to be brought down, reducing supply chain cost, and creating end users are key drivers. Economy of scale is a very important aspect if the hydrogen economy has to realize its potential otherwise it will remain limited to few pilot scale projects that have been happening across the globe for decades,” added Dr Pandey.

“I strongly believe that the path from grey hydrogen to green hydrogen will happen in steps. The first step will be the transition from grey hydrogen to blue hydrogen,” said Naveen Ahlawat, Head-Coal Gasification Project, Green Hydrogen & CCSU, Jindal Steel & Power Limited.

Ahlawat added further: “We are capturing 2000 tonnes of CO2 at our plants and releasing it into the atmosphere. Now we are looking at ways to utilize this CO2with concentration of more than 99%. We can use this CO2 to make chemicals such as ethanol, methanol and biological usage to make algae, peptides, proteins. It is not going to happen overnight but step by step. The coal gasification with Carbon Capture Utilization (CCU) has got the best economical sense right now if we compare it with green hydrogen. If we add in the value chain, the price of the hydrogen will be US$ 1.2 to US$ 1.3 per kg which is amazing economics. It can be utilized for various purposes. If we use 100% hydrogen to make sponge iron, we might encounter a drop of temperature. A lot of advancements are happening in this regard. Right now the trial and error experiments are going on in terms of mixing 20%-30% hydrogen and natural gases. Maybe in the next 2-3 years we will have a clear picture on how to move forward.”

“Hydrogen being very low density has to be compressed for use in sufficient amounts in any given volume. Therefore, compressed hydrogen cylinders are typically carbon fibre composite cylinders so as to make the carbon storage capacity significantly higher. While these are the most popular forms of hydrogen storage, for transporting the hydrogen over long distances and in large volumes, pipelines are the most best suited,” says Dr Ashish Lele, Director, CSIR-National Chemical Laboratory.

“Hydrogen is stored anywhere between 100-1100 bar and different applications need different pressures of hydrogen. The liquid form of hydrogen is essentially by liquefying it at sufficiently high cryo conditions and that is done at -200 degree Celsius. The liquefaction gives you much cryometric capacity which means in the same volume you can store hydrogen of much higher capacity. But there is an energy penalty for liquefying. The second type of liquid is Liquid Organic Hydrogen Carrier (LOHC) and in this case hydrogen is not liquefied but rather stored as a chemical in this molecule. Then you have to extract the hydrogen out of the molecules through some chemical process, typically a de-hydrogenation process. The most favoured carriers of hydrogen are toluene, 23DBT or even methanol and ammonia. The third is the solid state hydrogen where it is stored as solid mass in the form of metal hydride or other forms where it is physically absorbed,” Dr Lele.

Amrit Singhdeo, Senior Managing Director, FTI Consulting commented: “Hydrogen today doesn’t compete with any other technology on a commercial scale. If we are developing a hydrogen economy, we are doing it for the sake of a path to net zero. Hydrogen has an important role to play in that pathway because it is complementary with other green technologies such as renewable energy and electric vehicles. At the right time it will fit in perfectly but right now the technology is premature to compete with battery storage at a grid scale. Larger scale hydrogen will overtake the battery but again that depends on the configuration at the plant. The technologies must complement each other.”

The NextGen Chemicals & Petrochemicals Summit 2022 was supported by the leading names of the industry. The platinum partner was Elliot Group. Regulatory Knowledge Partner was GPC. Gold partners of the event included Ingenero, Premier Tech, Carbanio and Deepak Nitrite. Among the associate partners were PIP and Huntsman. The industry partners of the event included AMAI, Croplife India, and ACFI.

Subscribe to our newsletter & stay updated.