The real work and business advantages come when focusing on Scope 3 emissions generated beyond company’s walls

India has pledged to achieve Net Zero emissions by 2070, a goal requiring radical transformation and a shift towards non-fossil energy sources. This includes the adoption of hydrogen, solar, wind, and methane energies near points of use. Organizations are key players in this effort, focusing on reducing greenhouse gas emissions across their operations, which is only the beginning of the journey

The real work and business advantages come when focusing on Scope 3 emissions generated beyond company’s walls.

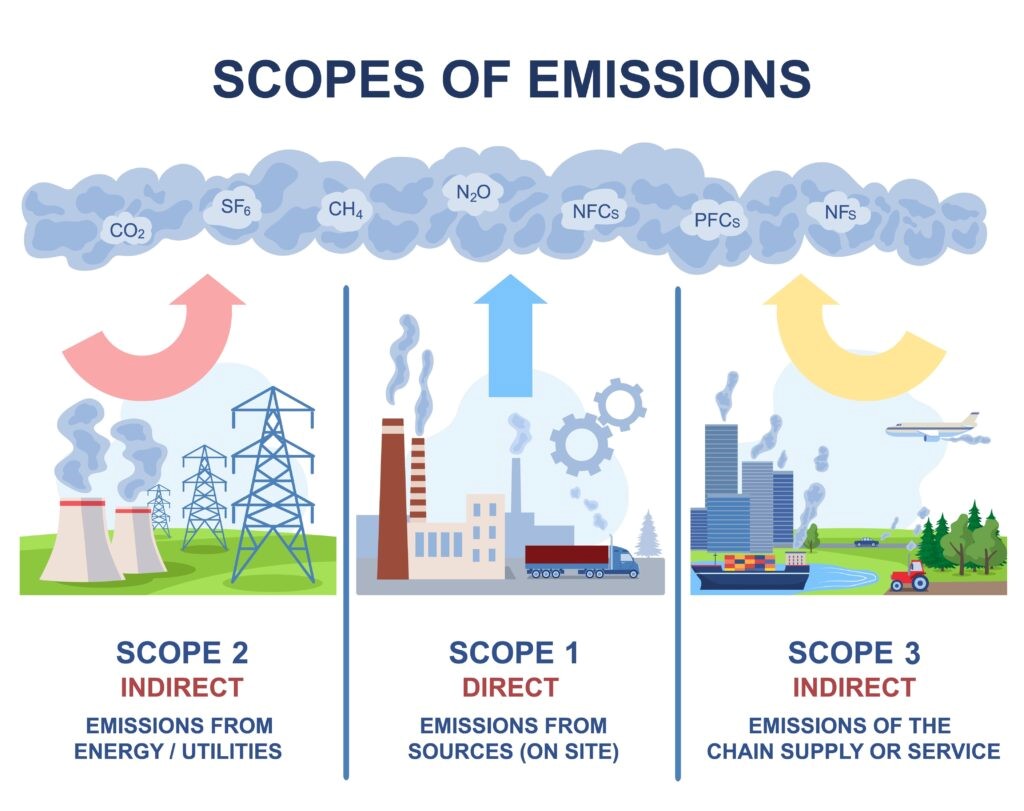

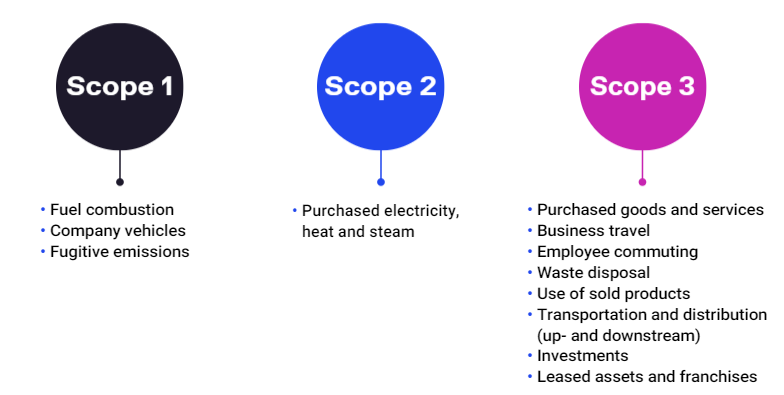

Definitions of scope 1, 2 and 3 emissions

Scope 1 emissions cover emissions from sources that an organization owns or controls directly for example from burning fuel in Boiler to produce steam & power.

Scope 2 emissions are the emissions that come indirectly from where the energy is purchased and used is production. For example, the emissions caused when power generated by Power producer and that power/electricity that we use in factories and offices, this will fall into emission 2 category.

Scope 3 emissions are the emissions that are not produced by the company itself and are not the result of activities from assets owned or controlled by them, but by those that it’s indirectly responsible for up and down its value chain. An example of this is when we buy, use and dispose of products from suppliers.

Why should an organization measure its Scope 3 emissions?

Measuring Scope 3 emissions has several benefits. For most businesses the majority of their GHG emissions and cost reduction opportunities are outside their own operations. Addressing Scope 3 emissions can help advance an organization’s decarbonization and sustainability journey.

Scope 3 emissions allow businesses to:

* Assess where the emission hotspots are across their value chain to prioritize reduction strategies.

* Identify which suppliers in terms of their sustainability performance.

* Inform decision making across procurement, product development and logistics teams regarding which interventions can deliver the most significant emission reductions.

* Encourage product innovation to create more sustainable and energy-efficient products.

* Advance their climate strategy to create genuine, quantifiable, and visible change.

* Positively engage with employees to reduce emissions from business travel and employee commuting.

Sustainable Sourcing:

Driving supply chain collaboration

* No company can move alone. This is especially the case when emissions are a result of activities like manufacturing, Sourcing/procurement and in totality complete supply chain. Hence, the industry is focusing more on collaboration between suppliers, distributors, contract manufacturers, and the rest of stake holders.

Transitioning to Renewable Energy

* Purchased electricity accounts for a major share of scope 3 emissions. The industry is now taking steps to procure renewable energy across their operations and value chain. Strategies include:

* Installing onsite solar, wind, or other renewables at owned manufacturing facilities.

* Procuring offsite renewable electricity through power purchase agreements with utilities and clean energy developers.

* Working with suppliers and manufacturers to switch to renewable power.

Sustainable Packaging

* Collaborating across the packaging value chain. So it is with suppliers, manufacturers, and waste management partners. It implements circular solutions.

* Joining decarbonization program or industry groups. This is to align with standards and best practices. These are the practices that enable the systemic change needed in packaging sustainability.

* Investing in innovation around biodegradable materials, digital watermarking, refillable/reusable packages, and other advances to close the loop.

* Educating consumers on properly disposing of or returning packaging. It is for recycling through labeling and awareness campaigns.

* Taking a holistic view – rethinking packaging design, materials procurement, manufacturing, reuse models, recovery processes as an integrated system.

* Using procurement and R&D influence over packaging design and production. This is to significantly improve lifecycle impacts.

Five steps to implement sustainable procurement Scope 3

Here's a five-step approach to help get started on the right path:

Evaluate the state of sustainability in your organization

Start by reviewing the current state of the organization’s procurement practices and how they align with sustainability goals.

What does the organization buy? Who does it buy from? What are the ESG impacts? How do your practices compare against industry standards or sustainability frameworks? Answering these questions will help to identify gaps and areas for improvement.

Define sustainability goals

After evaluating current procurement practices, it’s time to define ESG goals and corresponding Key Performance Indicators (KPIs). This will help you to define what business aims to achieve in terms of sustainability and how it’s going to get there whether it’s reducing carbon emissions, encouraging fair labor practices, or sourcing more sustainable materials.

These goals and KPIs can guide efforts in the right direction, keep accountable, and provide a way to measure progress toward sustainable procurement.

Select the right suppliers

Choosing the right suppliers is one of the most critical procurement decisions. Implementing a strict selection process can help evaluate whether a potential supplier shares values and meets standards in terms of environmental and social issues.

The process could involve sustainability assessments, pre-qualification questionnaires, and audits to ensure suppliers’ practices align with sustainability goals. Make sure to check whether supplier uses an environmental management system (EMS), legal compliance, and overall environmental and social impact.

Set policies and procedures

It's now time to develop a comprehensive sustainable procurement policy. This should lay out goals, plan to achieve them, and the KPIs use to track progress. It can also include things like criteria for selecting suppliers, sustainable purchasing guidelines, and how to plan to monitor and evaluate supplier performance.

It serves as a North Star for procurement teams and suppliers, ensuring everyone's on the same page about your sustainability standards. Communicate sustainable procurement policy, mission, and targets to you and employees. Offering training or resources can ensure everyone understands their responsibilities.

Measure and report

Make sure to regularly monitor your performance against your sustainability targets. Gather data from your key suppliers and use high-quality secondary data such as industry emission averages or insights from external data partners for a complete picture of your impact. Use this data for progress reporting and make necessary adjustments for continuous improvement.

Conclusion

Achieving Net Zero by 2070 requires concerted efforts from organizations to reduce emissions across all scopes. By focusing on sustainable sourcing, transitioning to renewable energy, and implementing comprehensive procurement strategies, businesses can significantly contribute to India's decarbonization goals. Through collaboration, innovation, and a commitment to sustainability, a greener and more sustainable future is within reach.

Subscribe to our newsletter & stay updated.