Industry decarbonisation is feasible but reducing carbon dioxide (CO2) emissions in these sectors is relatively difficult

At the COP26 UN climate change conference in Glasgow, many countries reaffirmed commitments they made to limit global warming at COP21 in Paris in 2015. India’s COP26 commitments were described as “ambitious” and “path-breaking”. This included commitments to achieve net zero emissions by 2070; increase non-fossil energy capacity to 500GW by 2030; bring the economy's carbon intensity down to 45% by 2030; fulfil 50% of its energy requirement through renewable energy by 2030 and reduce total projected carbon emissions by 1bn tonnes by 2030.

These commitments to significantly reduce carbon intensity are a tall order and would not be possible without a significant contribution from industry. Industrial processes alone account for around 29-30% of global greenhouse gas emissions – decarbonising industrial processes is a top priority.

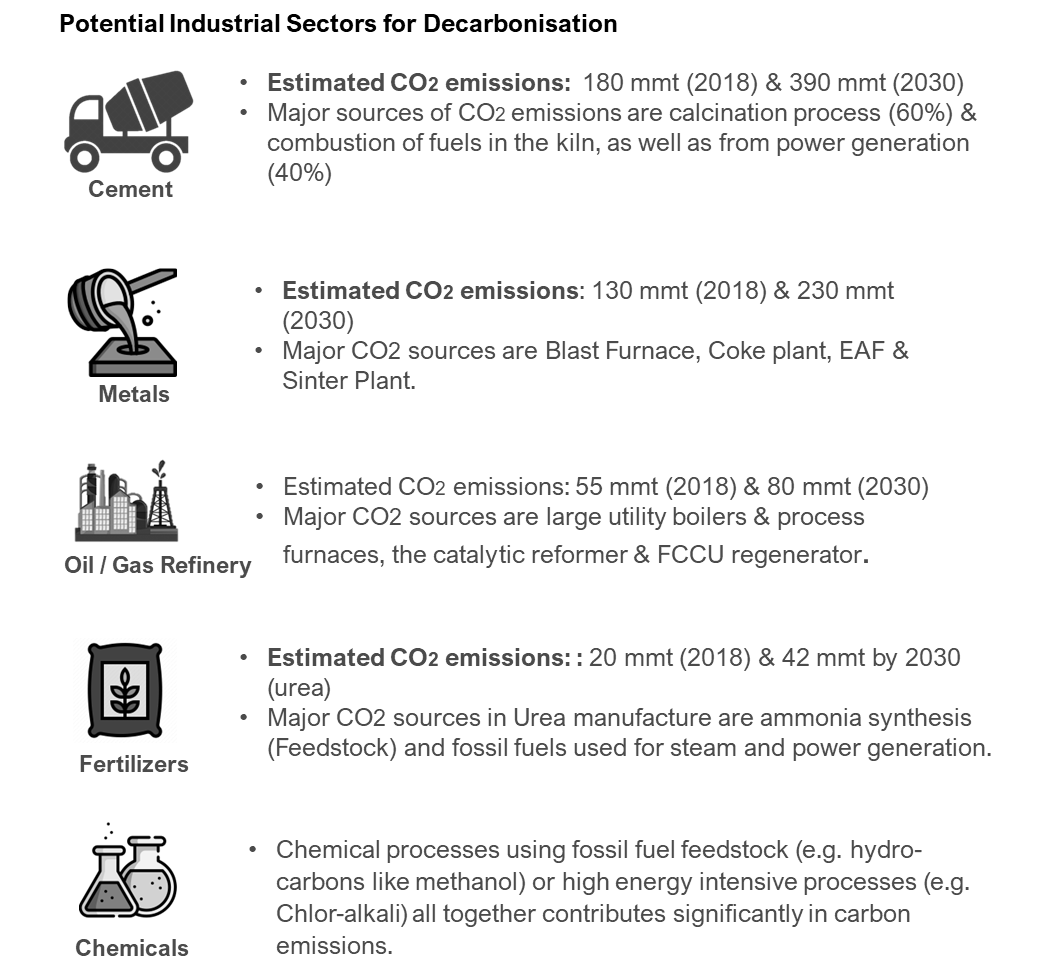

Potential Industry Sectors for Decarbonization

Industry sectors that are critical in terms of climate impact include cement, fertilisers (including ammonia for urea production), ferrous and non-ferrous metals, refineries, and downstream petrochemicals, as these are the sectors having a relatively high share of emissions from feedstocks and require high temperatures compared to other sectors.

Cement, metals (ferrous and non-ferrous) and oil/gas refinery has been accorded importance mainly because of their sheer size and emission intensity.

Similarly, in the fertiliser sector, decarbonising urea production is a priority because of the predominant use of fossil fuels as feedstock, although there is also good potential for decarbonising other phosphatic fertilisers.

Challenges in industry decarbonisation

Industry decarbonisation is feasible but reducing carbon dioxide (CO2) emissions in these sectors is relatively difficult for several reasons – some technical and some economic.

If the bulk of the emissions is from irreplaceable feedstocks, it is not easy to reduce them through process changes as it also entails changes in the dependent processes. Secondly, replacing fossil fuels with the generation of high-temperature, high-pressure steam using green sources of electricity or energy also involves considerable changes in furnaces and burners.

Investment levels are also economically prohibitive when technology transition is involved. Typically, projects in these sectors are high scale and have a long lifespan (over 30 years with maintenance). Process changes and retrofits in the existing units are therefore complicated, costly and require advanced and careful planning.

These changes would also have an impact on the marketability of the final products as a substantial increase in capital and operating expenses would push the final product price upwards. These products –cement, fertilisers, petrochemicals and steel –are commodity products traded globally. The price sensitivity of these product markets deters producers from adopting low-carbon processes and technologies.

Decarbonisation options

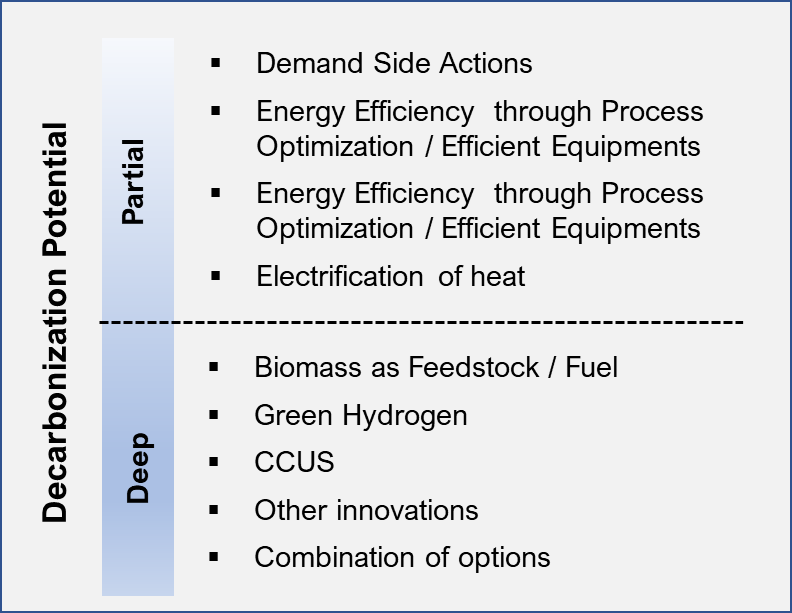

There are several options for decarbonisation. (1) Demand-side actions: reducing demand for resources by reuse, recycling, or replacement with green alternatives; (2) Energy efficiency: improvements in efficiency through process debottlenecking and optimisation or by using better energy-efficient equipment; (3) Electrification of heat: substituting fossil fuels for heating with renewable electricity; (4) Biomass as feedstock or fuel: replacing hydrocarbon feedstock or fossil fuels with sustainably produced biomass; (5) Green hydrogen as fuel or feedstock: replacing feedstock or fuel with green hydrogen; (6) Carbon capture, use and storage (CCUS): using a suite of technologies to capture CO2 emissions from large industry outputs and either using it in processes requiring CO2 or storing it; (7) Other innovations: using innovative processes, such as electrochemical production processes.

The selection of a specific decarbonisation option, or a combination of options, depends on the goal (partial or deep decarbonisation) of the industry. The optimum mix of decarbonisation options should be selected based on the local context and the most pragmatic solution in the long run. Important local factors include (1) the availability and cost of low-carbon energy sources – specifically, zero-carbon renewable electricity and sustainably produced biomass; (2) access to storage capacity for captured CO2, along with public and regulatory support for carbon storage. The other factor that could affect the choice of options is the project stage (greenfield or brownfield).

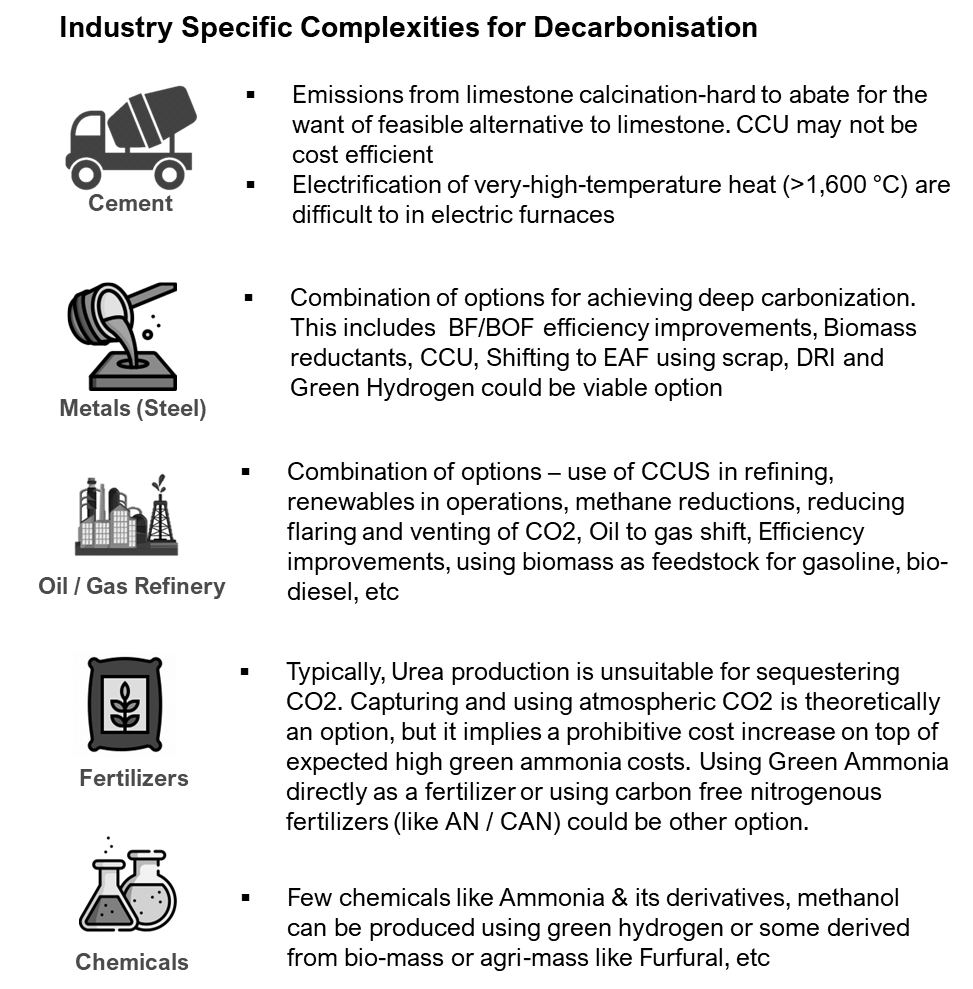

Industry Complexity Index for Decarbonisation

Each industry sector has different decarbonisation challenges. These factors are captured in the Industry Decarbonisation Complexity Index, including (1) availability of technology options for deep decarbonisation; (2) cost and effort involved in acquiring and adopting new technology options; (3) industry willingness. which depends on global competitiveness; (4) maturity of new technologies – high levels of complexity are associated with CCU and CCUS and the replacement of feedstock with green feedstocks, which are costly and not readily available.

The optimum mix of decarbonisation options depends on the availability of technologies and the economic feasibility of implementing them in the local context.

Each industry should prepare a practical roadmap setting out how to achieve the best possible level of decarbonisation. This transition should be aligned with technical advances in renewables, green hydrogen, ammonia production and CCUS.

How to accelerate the pace of decarbonisation

The pace of decarbonisation hinges on a dual transformation of energy and industrial sectors and support from all stakeholders.

All key stakeholders must come together to harness opportunities for collaboration, which are mutually beneficial. For example, industrial companies might need to co-invest in large renewables parks, CCS infrastructure, and R&D initiatives in emerging decarbonisation technologies. The role of the public sector and government is also crucial in setting the pace of decarbonisation. Government can accelerate change by pushing state and regional governments to adjust regulations and incentives to support decarbonisation.

Now is the time for industries to begin the transition, but it will be a long journey. Joint planning and support from government and other stakeholders will help India’s industries to set important decarbonisation milestones and overcome barriers along the way.

Subscribe to our newsletter & stay updated.