Focus on hydrogen is accelerating the transition to more sustainable forms of energy while still supporting current energy models

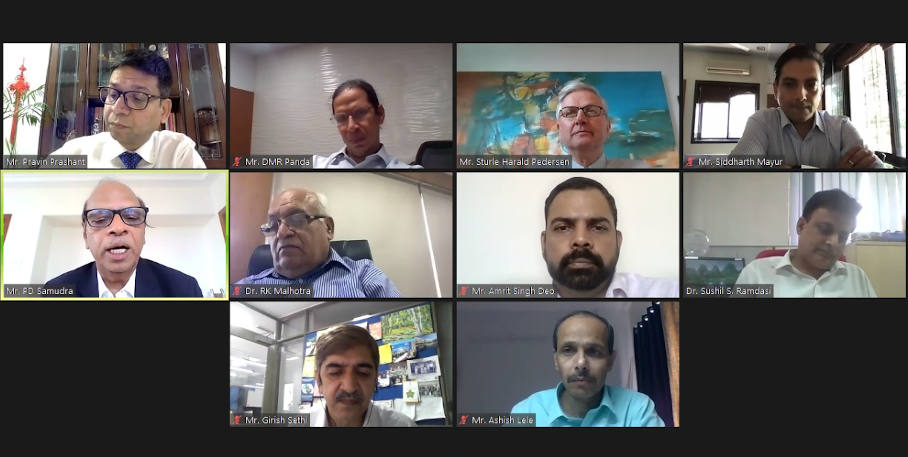

Leading experts discussed how green hydrogen is a fast emerging next-generation fuel as it supports a gradual transition towards lower-carbon sources of energy and can be used as a feedstock gas for various industries at the latest E-conference on ‘Hydrogen: The Next Clean Energy’ organized by Indian Chemical News.

Too much analysis can lead to paralysis as the world is moving fast on hydrogen, said P. D. Samudra, CEO & MD, Thyssenkrupp Industrial Solutions (India).

“To meet the Paris Agreement on climate change targets, we have to bring down the greenhouse gases emission by 2 degrees globally. The government has rightfully made the policy and we have achieved some progress. There is an upcoming investment opportunity of US $44 billion. Reliance and Tata Power will work together, NTPC is planning a pilot plant. There is going to be a massive shift towards alternative fuels. At the same time, the cost of hydrogen has to be brought to the price of US $2 per kg on the power side. Apart from encouragement from all the big industries, real growth could take place at the smallest level. It will provide a tremendous opportunity for smaller industries,” Samudra added.

Outlining the policy roadmap, Sturle Harald Pedersen, Chairman, Greenstat Hydrogen India, said : “Hydrogen is crucial for India in terms of catching up and becoming a leader. The public and private Indian doesn't have to reinvent the wheel but benefit from collaboration. More than 160 companies are ready to work with Indian academia and industry. We have leading research institutes that are ready to partner and there are projects in process. The government must provide the right policies. The National Hydrogen Mission is a step in the right direction. The hydrogen clusters and special incentives are required."

"Government must step up the funding for R&D to create new materials, improve quality and energy efficiency. It must also facilitate the pilot projects to cut down on risk. Any accident will result in a loss of public trust and investment. So safety guidelines and practices are important. It is also critical to avoid the red tape,” added Pedersen.

Hydrogen went through the hype in the past but this time it is for real, says Ashish Lele, Director, CSIR-National Chemical Laboratory, who believes that the interest is exponentially growing.

"The role of R&D is important for technology maturity and large scale production of technologies to make hydrogen viable. We need to do a lot of value engineering into products as they come to India. We must adopt a lot of technology as per geography settings. CAPEX reduction and especially durability that is important as climatic conditions are different than in Europe and the US. The scientists at National Chemical Laboratory are trying to understand the nitty-gritty of developing an efficient, low-cost component crucial to building fuel cells,” Lele added.

Girish Sethi, Senior Fellow and Programme Director, TERI said, “One of the reasons for the hydrogen push is the fuel demand. From the current demand of 6 million tonnes we will require 30 million tonnes by the middle of this century. Demand will be from industry especially the steel sector which will triple its production to 450 million tonnes besides oil and refinery. Once we have hydrogen available at US $2 dollar per kg, the use of hydrogen for industrial applications will register a jump. Emphasis has to be on the feasibility of pilot projects, end-users, technologies from Europe and approaching international bodies for funds.”

We had long back visualized the hydrogen as a future fuel, Dr. R. K. Malhotra, Director General, FIPI, said sharing a different perspective. “We can't immediately stop non-renewable fuel production as the natural coal and oil reserves still have stocks in abundance. At the moment, hydrogen should be used as a storage medium. Whenever we are not able to use solar energy, we can convert it into hydrogen and keep it stored. Blue hydrogen will find more traction and in fact, will compliment green hydrogen. While blue hydrogen will play a role in the next 20 years, the latter part of the century will have green hydrogen including biomass playing a vital role in fuel generation. If we have to move to a hydrogen economy, we can't overlook the role of oil and gas industries and blue hydrogen. It can't be just green hydrogen but keep considering all forms.”

As per DMR Panda, GM - Hydrogen, NTPC, while the government’s target is 450 gigawatt, India's actual demand might not be higher. “We have coal reserves that are not running out sooner so we have to devise a policy to create synergy. At NTPC, we aim to transform our power centres into chemical centres to make green chemicals from there. The current process is heavily dependent on diesel, so we need to make green hydrogen. We are continuously working on the new green hydrogen pilot projects. Currently, we have six projects, out of which three are green hydrogen. We have various models and whatever works, in the long run, is good.”

“Government has leapfrogged from BS-4 to BS-6 skipping BS-5. We have reduced the emission levels by 6% but there are challenges,” mentioned Dr. Sushil S. Ramdasi, Deputy Director, Automotive Research Association of India (ARAI).

“Customer acceptability is very important. Hybrid vehicles are low cost and even give 20% saving. CNG and methanol with electric vehicles are good experiments. These will help in the increasing volumes of EV and thus increase penetration. Heavy commercial vehicles travelling 500 to 800 km daily need to stop after 4 hours. Lighter vehicles can have a small solid oxidized fuel cell technology. We should not be constrained only on hydrogen. Among the challenges is the reduction in the cost of fuel cell and storage technology. The types of cylinders that are required for storage have a high cost and are imported currently,” Ramdasi commented.

Building local technologies is possible in India and by 2022, 98% of components will be made locally,” says Siddharth Mayur, Founder, h2e Power Systems. “For example, solid oxide fuel cells can be made in India. We don’t need high value or rare chemicals to create them. The ecosystem is already there and vendors are capable of developing the components from mobility to hydrogen generation. We have developed the cheapest electrolyzer in the world with huge export potential. My office is running on the hydrogen fuel cell for the last two years and we are building a gigawatt facility in Pune.”

A lot of work has been done in the area for the last 15 years and a lot of R&D work has been done, informed Amrit Singh Deo, Senior Managing Director, FTI Consulting. “Time to reflect on how much we have achieved so far and we need to learn from Japan and Korea who are using the cluster approach. The volumes will determine the future besides the funding for large demonstration projects. This is going to be a long way in the absence of monetary support. Therefore, we must aim to achieve at least half a billion-dollar fund by 2025.”

Subscribe to our newsletter & stay updated.