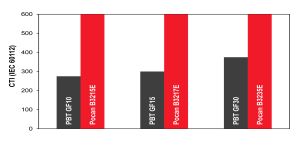

With their tracking resistance, the new compounds score the best possible rating of 600 in the CTI A test

Specialty chemicals company LANXESS has developed new polybutylene terephthalate (PBT) compounds for use in electrical and electronic assemblies. Under the name Pocan E, the company is now offering a product range comprising short-glass-fiber-reinforced grades that are especially suited to applications in e-mobility and the electrical/electronics (E/E) industry thanks to their tracking resistance and insulation properties.

With their tracking resistance, the new compounds score the best possible rating of 600 in the CTI A test (Comparative Tracking Index – IEC 60112) and therefore meet the requirements of the highest insulation class according to IEC 60664-1.

“Previously, glass-fiber-reinforced PBT compounds with such high tracking resistance were not readily available on the market. We have now closed that gap. We have also succeeded in providing the materials with further advantages such as optimized mechanical properties as well as excellent flowability, hydrolysis resistance, and flame-retardant properties. In addition, they are highly suitable for coloring – orange, for example,” explains Dr. Claudia Schmid-Daehling, who shares the responsibility for PBT product development at LANXESS. High suitability for coloring is important for various safety-relevant components such as high-voltage connectors that must be clearly color-coded.

Plastic parts for electrical and electronic components must increasingly be more resistant to undesirable creepage currents. Reasons for this include the strong currents and high voltages in electric vehicles, the trend toward miniaturized device components, and the ever-decreasing distances between metal contacts in connectors and terminals.

Creepage currents occur when electrically conductive paths – facilitated by impurities – form on the surface of insulating materials, such as thermoplastics. This results in short circuits and, in the worst-case scenario, damage to the device. If insulating materials have a high tracking resistance, this reduces the risk of such defects.

The CTI A test in accordance with IEC 60112 has become an established testing method. Even though the maximum CTI A value is 600, a plastic can also be used where higher voltages of up to 1500 volts (direct current) are present. “This means that our new Pocan E product range can also be used with the significantly higher rated voltages that are required for rapid charging of electric vehicles, for example.”

Subscribe to our newsletter & stay updated.