BASF’s polyarylethersulfone combines exceptional stability with optimal processing where other materials fail to meet the requirements

BASF offers a unique partnership to the energy sector: a tailored portfolio of polyarylethersulfones (PSU, PESU, PPSU) for components in water electrolyzers used for producing green hydrogen – combined with application know-how and reliable local technical support for part design.

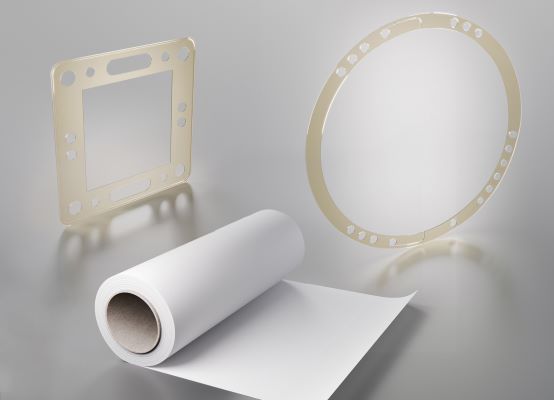

Backed by BASF’s deep understanding of complex injection-molding applications and membrane casting, BASF helps customers in upscaling electrolyzer technology, thus pushing the transformation to clean energy. BASF’s portfolio for electrolyzer parts includes Ultrason grades for frames, gaskets and separator membranes. This can be experienced first-hand at the BASF booth at Fakuma 2024, Germany where an electrolyzer frame sample will be exhibited.

Ultrason is ideally suited for metal replacement in various components of alkaline water (AWE), proton exchange membrane (PEM) and anionic electrolyte membrane (AEM) electrolyzers. The amorphous polymer shows outstanding temperature and chemical resistance. Its excellent performance under highly demanding conditions includes thermoplastic processing for structural parts and constant high purity for separator membranes.

BASF’s polyarylethersulfone also enables long lifetime of electrolyzers: it withstands the high compressive forces of electrolyzer systems and shows great hydrolytic stability. The BASF thermoplastic can be used for small as well as large injection-molding and extrusion components. All these advantages lead to lower-weight electrolyzers and higher freedom of design for different construction needs when compared to metal.

Subscribe to our newsletter & stay updated.