Toray Industries, Inc., announced today that it has developed the world’s first mass production technology for rare-earth-free zirconia balls. The highly durable balls could grind and mill ceramic materials for multilayer ceramic capacitors (MLCCs) and electrode materials for lithium-ion batteries.

This advance could enhance the reliability diverse products and stabilize their supplies. It could help customers cut manufacturing costs by replacing balls less frequently.

Toray will initiate sample work early in the fiscal year ending March 2024. It aims to begin mass production by the close of the term.

The prime application of zirconia balls is to disperse and powderize materials and polish surfaces. The company developed Torayceram high-performance ceramics, used in ceramic materials for MLCCs and electrode materials for lithium-ion batteries.

The growing sophistication of smartphones in recent years has increased demand to improve the reliability and supply stability of raw materials for products. The use of zirconia balls as electrode materials for lithium-ion batteries in electric vehicles and other applications should grow. This has intensified pressures to cut costs and develop more durable zirconia balls.

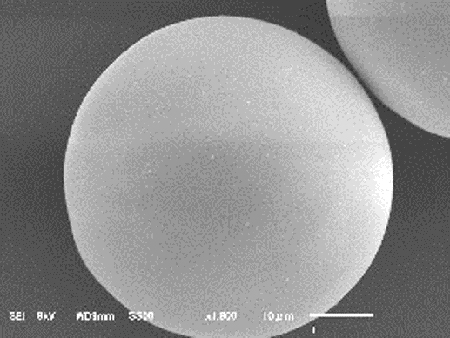

Toray thus developed a mass production technology that minimizes the degradation of crystal structures on zirconia ball surfaces. It redesigned part of the structure of these balls, making them much more durable that conventional counterparts. This minimizes contamination from zirconia balls in grinding and milling ceramic materials for MLCCs and electrode materials for lithium-ion batteries, improving and stabilizing the quality of target substances. The redesigned structure enables sintering at 1,300°C or less, compared with 1,500°C for regular processes, for lower carbon dioxide emissions.

Another key benefit of Toray’s technology is that it is free of yttria, a rare earth metal oxide that is a common stabilizer in zirconia balls. This eliminates country of origin tracing concerns.

The company will take advantage of the high durability of its technology by exploring ways to regrind the surfaces of zirconia balls and recycle them. It will accordingly collaborate with customers in evaluating a recycling system to help reach Sustainable Development Goals.

Toray will leverage core technologies in organic chemistry, polymer chemistry, biotechnology, and nanotechnology to undertake R&D and conceive innovative materials that drive fundamental social change. In so doing, it will endeavor to materialize its corporate philosophy of contributing to society by creating new value through innovative ideas, technologies, and products.