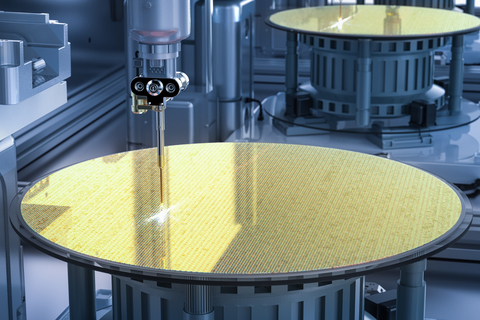

Chemplast Sanmar inaugurates Phase 1 of the new multi-purpose block at the Custom Manufactured Chemicals Division, Berigai

Project activities related to the second phase of the production block are also underway and are expected to be completed over the next 8 months.