Huge increase in production capacity in Europe, North America and Asia

Röhm firmly believes that Plexiglas molding compounds will remain an essential material for numerous industries in future, offering ideal solutions for new requirements and trends. Despite the difficult conditions the chemical industry in general faces as a result of global crises, the company remains committed to its ambitious investment programs for polymethyl methacrylate (PMMA) production.

With production capacity hugely increased worldwide and a broad portfolio of PMMA special molding compounds under the plexiglas, pleximed and cyrolite brands, the molding compounds business unit is in a very strong position.

“The PLEXIGLAS molding compounds product portfolio is being constantly developed to meet the needs of the market,” comments Siamak Djafarian, Head of the Molding Compounds business unit. The most recent addition is PLEXIGLAS proTerra molding compounds, which combine a reduced carbon footprint with the proven performance of the brand PMMA.

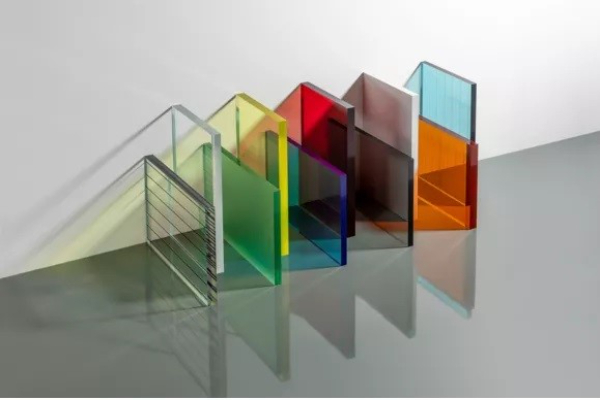

At its largest global production site for Plexiglas molding compounds in Worms, Germany, the company added a new production line in February 2024, as well as an additional compounding facility for colored PMMA products. The new facility uses a more energy-efficient production process that significantly reduces the carbon footprint of molding compound production. After all, sustainability is integral to Röhm’s business strategy.

Mid-2024 also saw Röhm significantly increase its production capacity at its Wallingford plant in Connecticut, USA, by converting the existing production line to enable faster delivery to customers. The Wallingford plant employs more than 50 people and operates multiple production lines producing special PMMA molding compounds. It is also an important production site for cyrolite, a high-quality, transparent, acrylate-based plastic that is predominantly used in medical technology. In China, too, Röhm has continued to enhance its market position by expanding the capacity of its PMMA facility in Shanghai and by extending the compounding facility.

Through investments in cutting-edge production technology, capacity expansion and innovation, Röhm and its Molding Compounds business unit are more than ready for the future. “We are the only global manufacturer of MMA and PMMA with production facilities with downstream compounding in the three key regions of Asia, Europe and North America. That makes Röhm a leading manufacturer of PMMA molding compounds worldwide. Our products, our delivery reliability with short delivery routes, and our on-site technical service make us a partner that customers all over the world can trust,” says Djafarian emphatically.

Subscribe to our newsletter & stay updated.