Software applications enable complete lifecycle of advanced analytics in improved business and production results

Allison Buenemann, Industry Principal – Chemicals, Seeq Corporation shared her presentation titled, ‘How to operationalize your analytics in chemical industry' at the NextGen Chemicals & Petrochemicals Summit 2021 organized by Indian Chemical News on 7-8 October, 2021.

“Operationalizing analytics in the chemical industry requires the appropriate recording of the right datasets. Companies are generally using MS Excel which is inadequate and can’t give the results that are aspired for. There are disparate data sets which are based on millions of sensors, siloed on-premises data sources and variable data structures. However, despite having the humongous data, the information is poor. The insufficient tools provide manual data collection and rigid visualization capabilities. There are inadequate analytics functions and lack of innovation for SME. Therefore, it is not action oriented for operations,” says Buenemann.

Offering practical solutions from Seeq, Allison Buenemann said, “The data needs to flow between data scientists, engineers, managers and control rooms. Seeq offers browser based experience to the users where all these are connected. Following that the time series data needs to be analyzed and adding contextualization to the particular set of data helps users to focus on their interests. This is key basics before the users want to move to more complex predictive analytics, create models and their own data labs. To operationalize data from any sources, various kinds of data sets are published and shared on databases and links shared with managers.”

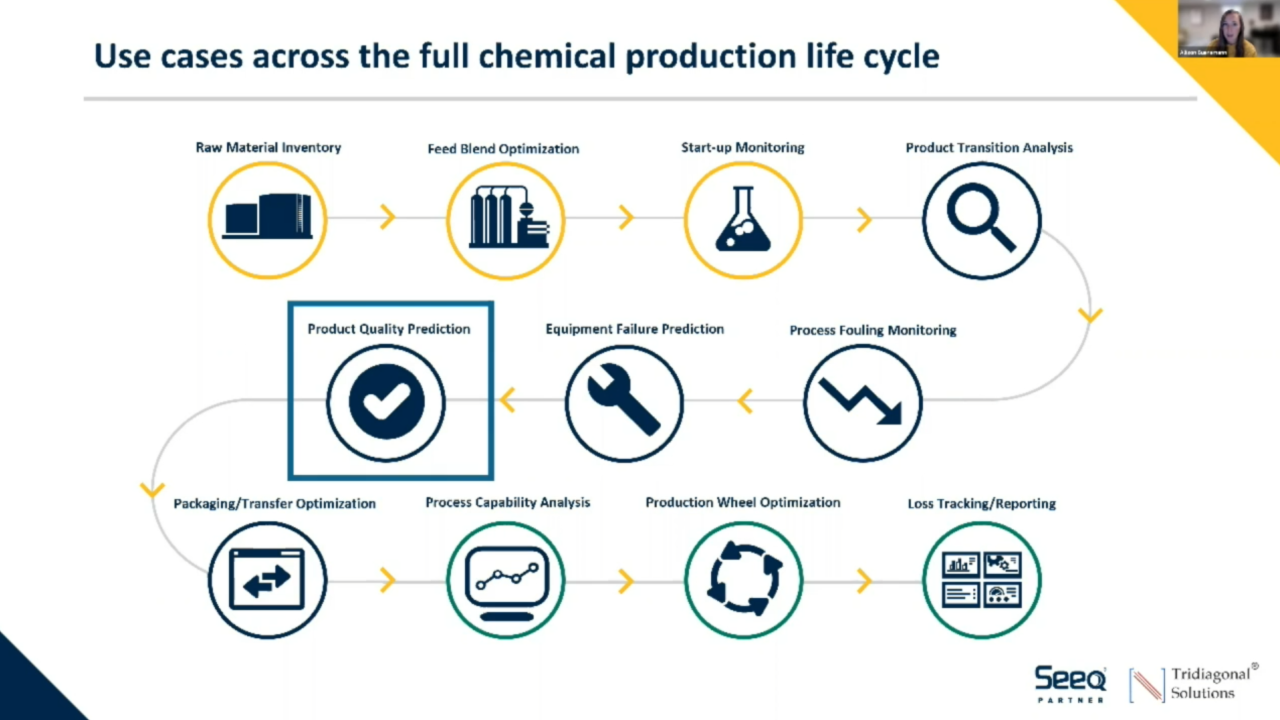

Buenemann commented, “There are a lot of opportunities for use cases across the full chemical production life cycle. Plants use retrospective data to do optimization. For example to predict product properties based on upstream conditions. The challenge is that the product quality is controlled using a feedback loop, making process adjustments based on downstream lab results. In this case predicting future lab results requires an understanding of process co-relations, residence times between equipment, and advanced analytics. The solution is to cleanse and delay input signals to create a predictive model. It helps in quantifiable annual margin loss opportunities besides near real-time projection of product property based on current conditions to inform process decisions.”

“Seeq is the first application dedicated to process data analytics. Search your data, add context, cleanse, model, find patterns, establish boundaries, monitor assets, collaborate in real-time, and interact with time-series data like never before. Seeq applications enable the complete lifecycle of advanced analytics, from first connecting to data to landing insights in improved business and production results,” added Buenemann.

Subscribe to our newsletter & stay updated.