This resin can lower connector production-derived carbon dioxide emissions

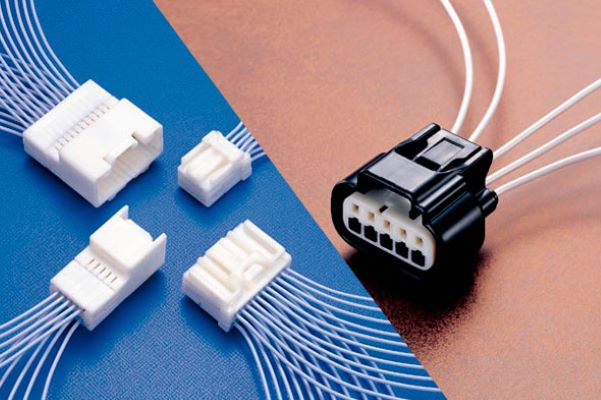

Yazaki Corporation and Toray Industries have jointly developed a recycled polybutylene terephthalate (PBT) resin grade that uses scrap materials from manufacturing processes to make connectors for automotive wire harnesses.

This resin can lower connector production-derived carbon dioxide emissions while offering the same performance properties as virgin materials.

Toray offers Ecouse Toraycon, a chemically recycled PBT resin made by depolymerizing and repolymerizing scrap from manufacturing processes. The downsides of recycling resins include contamination from foreign substances and degraded material quality. Through chemical recycling, the company provides recycled PBT resin that matches the quality of virgin material. This process includes rigorous quality control from depolymerization to compounding.

One challenge for Yazaki has been to stabilize the quality of recycled materials in highly functional parts, such as automotive wire harness connectors. It addressed this by optimizing the material properties and moldability of Toray’s chemically recycled PBT resin. It collaborated with Toray to develop a recycled PBT resin grade for connectors that matches the quality stability of existing PBT resin grades.

Through this joint effort, Yazaki and Toray will contribute to realizing a carbon-neutral, circular economy in the automotive industry.

Subscribe to our newsletter & stay updated.