To reach 5 million tons of green hydrogen production by 2030, industry needs incentives, access to electrolyzer technologies, better incentives, infrastructure and above all, right policies

Setting its national green hydrogen policy rolling, India has already set an ambitious target of producing 5 million tons per annum by 2030. While there have been a few positive steps to encourage private players such as tax breaks and plots to set up plants, experts still feel that there is a long way to achieve a well-established ecosystem.

“India certainly has a huge potential to become a global hub for green hydrogen and I hope that we will have all the right policies in place to make that happen. The challenge is that our current costs of hydrogen are very huge and that has to come down first. That would imply that the scale of production has to go up, costs come down with scale and that is where I think we are going to talk about government policies which are meant to enable that,” says Dr. Ashish Lele, Director, CSIR - National Chemical Laboratory (NCL).

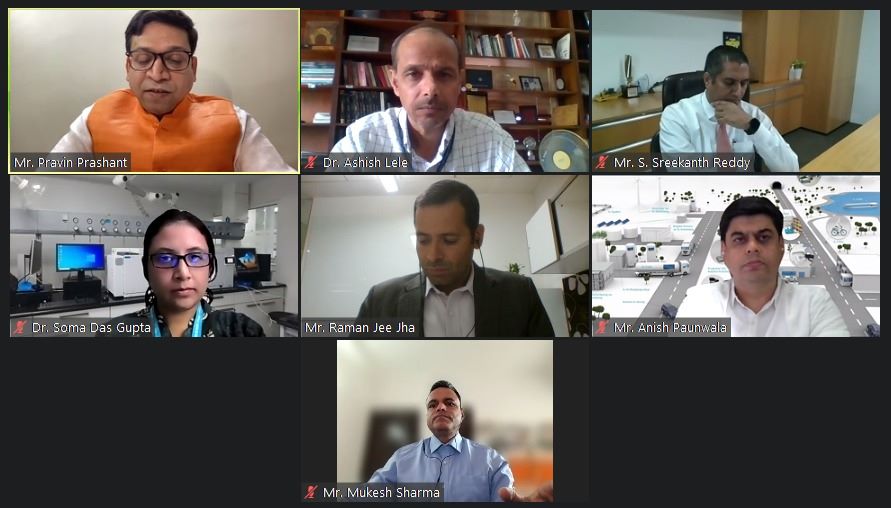

Dr. Lele spoke at the E-conference on "Hydrogen: Energising the Energy Ecosystem" organized by Indian Chemical News (ICN) on May 31, 2022. The virtual session supported by Agilent Technologies was moderated by Pravin Prashant, Editor, ICN.

“If you look at our road map, we are talking of five million tonnes immediately. We are talking of 12 million tonnes by 2040 and so on and that's somewhere in between 3035 gigawatts for 5 million tonnes, about 7080 gigawatts for 12 million tonnes. Now that's the kind of electrolyser capacity that we need and we need that pretty quickly. If that scale is brought in at the right time with the right speed, the costs for hydrogen can come down as the CAPEX of the electrolyzer contributes at least about 30%-35% of the total cost of hydrogen,” Dr Lele elaborates.

On policy requirements Dr Lele adds: “We have to put in place the policies that ensure not only the green hydrogen production but also its storage, safe transportation locally. We need good port infrastructure and if possible a good location from where you can supply hydrogen globally. The colour coding of hydrogen, the certification required for hydrogen, all that has to be put in place pretty quickly. I believe that with scale and with the way India is going in terms of renewable energy increase, the cost of hydrogen is bound to come down.”

One of the key challenges in the hydrogen product is especially with respect to its cost. While the renewable electricity cost is already coming down, we have to ensure that we match the hydrogen cost targets, says Mukesh Sharma, General Manager-Corporate Strategy, Indian Oil Corporation Limited.

“We have to go for an energy transition and our Prime Minister has already announced very aggressive target for the country to become net-zero by 2070. All our companies are in line with achieving that target of 5 million tonnes of green hydrogen production target, including the industry requirement, majority by refineries, petrochemical plants as well as fertilizer plants. And this also includes exports from India,” adds Sharma.

Sharma lists a few activities at OICL, “We have a tremendous investment plan for this green hydrogen. We have already announced a joint venture company with Larsen & Toubro for developing hydrogen assets for Indian oil as well as for the other companies in India. Indian oil is going to set up the first facility at Mathura refinery with the capacity of 5 KTA per annum which is close to 40 megawatts of electoral capacity. Overall it will be 120 MW of renewable energy power required for running the refineries as these operate 24* 7. Therefore, hydrogen requirements for these facilities will be on a continuous basis, and typically the power assets will be required at three times.”

The basic ingredient for the reproduction of green hydrogen is obviously the electrolyzer and India needs to cater to its futuristic demand, feels Milind V. Baride, Vice President, Tecnimont India.

“If we are targeting 10% of hydrogen use by the industry, that is an incredibly tremendous amount of hydrogen. At this scale, we are talking in Gigawatts of requirements. The question is, do we have an electrolyzer capability and capacity to produce hydrogen in the country so the first target will be to have an electrolysing manufacturing facility which can cater to the requirements, adds Baride.

“Another important point is the location of the hydrogen production units has to be nearer to the plants where it could be used. Since most of the refineries, steel plants, and fertilizer plants are located in different parts of the country, it is difficult to imagine a single production capacity of the hydrogen to be provided for all these industries. So this would mean it will need to be decentralized and kept nearer to the consuming point. The transportation which is the link to take the hydrogen from the produced area to the consumed area needs to be addressed,” emphasizes Baride.

“The current economics of hydrogen may not be appropriate for the industry to convert the intensity goes into hydrocarbons. For net zero by 2050, we have to be more than hopeful. The economics of hydrogen should push us to start adopting hydrogen in a big way. By 2025, few of the industries will invest into very large scale electrolysis where they are producing the green hydrogen and converting. The entire Indian industry is committed for becoming net zero by 2050. So, given the technical feasibility I think hydrogen probably would be the only choice,” says S. Sreekanth Reddy, Joint Managing Director, Sagar Cements Limited.

“India is the second largest producer of cement in the world, with approximately 350 million tonnes of cement consumption. For us to adopt hydrogen in a big way, this helps us in two things. One, cement being very large energy intensive is at the same time one of the largest producers of CO2. And for us to become net zero, I think Hydrogen would become a blessing. The adoption of hydrogen into our sector will happen in a big way once we address the cost issue.”

“Right now there are bottlenecks in terms of actually designing, manufacturing and operating of electrolyzer which has not been talked about. Another challenge to ensure a smooth supply chain. The blue hydrogen is also very critical and we should not ignore it for even to make a green hydrogen very popular, believes Anish Paunwala, Director, Linde.

Paunwala adds further: “Every green hydrogen production we want to export or any importing countries which we are looking at Japan, Korea, even in Europe, they all will have access to green hydrogen as well as blue hydrogen. So they are actually going to have the comparison. There is no price difference between the green and blue hydrogen. They only talk about clean hydrogen and there is same situation in India. We have a multiple of hydrogen production facilities which can be quickly converted into the blue hydrogen and make the application start which helps at least adopt the demand side of the hydrogen issues.”

“Before looking at export or export, we should look at our own consumption and supply part. We should target being self-reliant as put forth by none less than Prime Minister himself, says Raman Jee Jha, Director, Oil & Gas Industry Practice, PwC India.

Jha explains: “We need to look at various aspects when working to create a demand. I believe going directly for the green hydrogen could be the pathway. Maybe export import opportunities could be seen later on and rather we should look at our internal supply and demand. The technologies which are lower in cost, maybe we need to implement them first. We need to create suppliers and supporting infrastructure in a phased manner. On the cost part, if we are at $6 today, we would reduce cost by 78%. Majority of the cost we are expecting to come down because of the reduction in CAPEX by 2030, at least by 25% to 30%. Incremental technologies we can bring in hydrogen to the market, for example. GAIL has implemented hydrogen blending and they have reported back that up to 20% blending in natural gas is possible.”

Sharing information on hydrogen related technology solutions offered by Agilent, Dr. Soma Dasgupta, Application Engineer GC/MS, Agilent Technologies says, “Agilent has come up with energy and chemical analyses, which includes solutions that are pre-configured and chemically distinct to ensure rapid analysis of impurity compositions as well as their concentration. So these analyzers basically include an optimized method with method files for specific analysis, putting into a certain regulation. It has a quick start guide for faster implementation. It will also have reporting options as well.”

“The software will automate the calculation and report the data in a format which is specified with enough regulation. There are several models which can be used for this. It could be the 8890 GC system, which is an intelligent system and can deliver fast and accurate results with flexible configuration capabilities. So we can configure 89 zero GC as per the kind of regulation or the type of analysis which is required. Alternatively, there are smaller compact systems such as 990 Micro GC which can be carried to a field. In the green hydrogen space, there are ready made solutions where you can analyse hydrogen These methods have been tested by our scientific team and implemented at different customer sites.” Dr Dasgupta adds.

Here's the link to view full recorded version of the E-conference- https://www.indianchemicalnews.com/webinar/hydrogen-energising-the-energy-ecosystem-44

Subscribe to our newsletter & stay updated.