The new paradigms are Waste to Wealth, Circular Economy and Renewable Energy, particularly solar, wind and green hydrogen. Recycle Engineering, Process Intensification, Waste Minimization and Green Processes must be practiced for achieving sustainability

Sustainability is just now a buzz word but must be a ritual to be adopted by all stake holders. The UN Sustainable Development Goals (SDG) cover 17 of them but my personal opinion is that many of these might have been derived from the Grand Engineering Challenges mentioned in the 1999 report by the US National Academy of Engineering. We are all concerned about sustainability, health, vulnerability, and the joy of living and have been used to the linear economy. The material needs of society will require 3 Earths if the 3-R (reduce, reuse and recycle) strategy is not adopted for achieving the so-called circular economy. Plastics are an integral part of modern society. But plastic is the most misunderstood material due to the pollution associated with it and totally irresponsible society. So, the moot question is “Can we live without plastics?” The answer is resoundingly no but what about pollution? We must convert the waste into wealth by using novel and cheap technologies. Recycle engineering by physical, chemical and biological rate processes for the material and energy needs will be practised in the future by all stake holders and quite interestingly chemical engineering as a discipline will be at the hub.

There are enormous quantities of solid wastes lying all over, including plastics, tires, food, animal manure, woody biomass, construction debris and the like. Generation of heterogeneous and toxic MSW, heaps and heaps of it presenting an ugly site, is a real cause for concern. Among these solid wastes, plastic has received the maximum attention due to the widespread littering, production scale and visible environmental damage. Plastic was supposed to be a cheap and better alternative to paper which was responsible for denudation of forests. However, the benefactor became a curse over the years. Plastics are usually used for packaging because of their light weight, low cost, processability, high performance and easy availability. Polyethylene (PE) and polypropylene (PP) are some of the most used plastics in multilayer film packaging, among other applications. The Single Use Plastic (SUP), namely, polythene bags available freely are mainly responsible for their being discarded after use. It has no value as the commoner thinks. High durability of plastics leads to huge quantities of waste accumulation in landfills and oceans because most synthetic polymers are designed for longevity and performance rather than recyclability and degradability. The SUPs are used for sterile packaging, storage, transportation, and disposable medical parts which contribute to global waste. Approximately 380 million tons of plastics are produced annually worldwide and resulting in huge contributions to global waste and environmental pollution.

The Menace of Plastic Waste

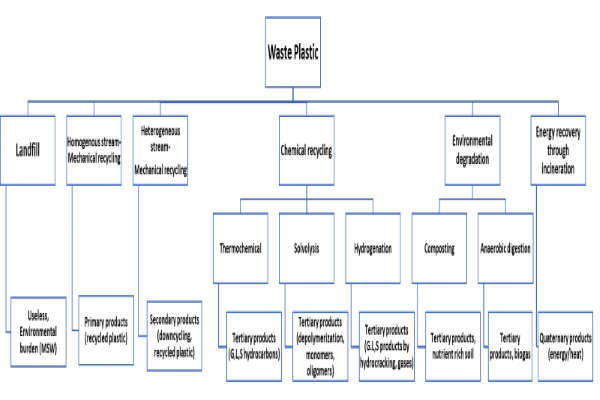

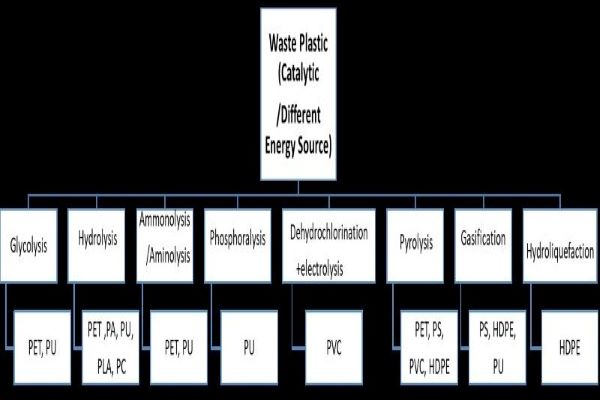

Plastics have been widely used as materials since the 1950s. The raw materials used for manufacturing plastic products mainly originate from non-renewable crude oil. The use of non-renewable feedstock for plastic production may increase from 6% in 2014 to 20% by 2050 considering the strong growth of plastic usage. It is estimated that over 9.2 billion tons of virgin plastics had been produced and the global annual production of plastic has already increased to 368 million tons in 2019. Due to the low production cost and versatile applications of plastic-based goods i.e., food industry, clothing, housing and transportation, the amount of produced plastic material is projected to still increase in the future. In contrast to the huge production, only 10% of total worldwide plastic waste has been recycled, while 14% has been incinerated and the rest has been discharged to landfills or ended up in the environment. The mismanagement and the lost opportunities in the recycling of plastic waste have resulted in global concerns, mostly related to widely spread plastic pollution of terrestrial and marine ecosystems. When plastic waste ends up in the environment it undergoes mechanical and chemical weathering down to micro and nano-plastic particles, which are considered emerging pollutants and attract significant attention as their impact on human health is not yet understood. Waste plastics, however, are considered as valuable but misplaced resources, which are complementary to non-renewable fossil fuels. The mismanagement of plastic waste urges the development of effective methods for common plastic recycling, until fully biodegradable and economically feasible plastic replacement solutions become available. Figure 1 provides some technology options to deal with waste plastic.

Figure 1. Waste plastic management technology options

Municipal Solid Waste

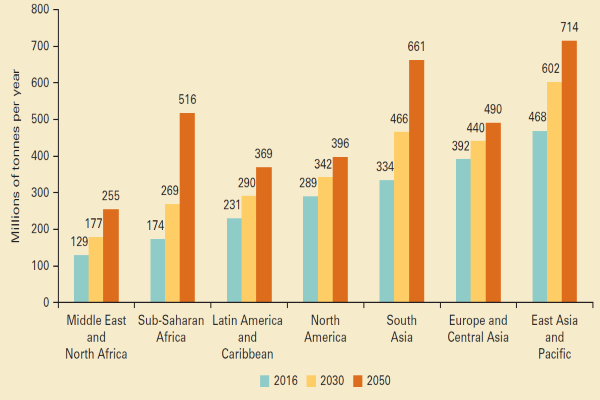

The world generates 2.01 billion tons of municipal solid waste (MSW) annually, in which it is predicted that one-third is not managed in an environmentally safe manner. Currently Waste generated per person per day averages 0.74 kilogram but ranges widely anywhere from 0.11 to 4.54 kg depending on the income level and place of residence (Figure 2). Even though they only account for 16 percent of the world’s population, the developed nations generate about 34 % or 683 million tons of the total waste. Single-use multilayer flexible packaging is a typical example of such non-recyclable waste that ends up in landfills and, eventually, in natural habitats. Approximately 8 million tons of plastics find their way into oceans annually, and the plastic pollution in oceans is predicted to overshadow marine fish by 2050. One-third of all plastic produced worldwide is too complex (e.g., complex structures, complex mixture of different polymers) or small to recover or recycle in a practical and cost-effective manner.

Figure 2. Solid waste generation (source: World bank)

Approximately 1.6 billion tons of carbon dioxide equivalent GHG were generated from solid waste treatment and disposal in 2016, or 5 percent of global emissions. Disposing of waste in open dumps and landfills without landfill gas collection systems is very common. Food waste accounts for nearly 50% of emissions. Solid waste–related emissions are anticipated to increase to 2.38 billion tons of CO2-equivalent per year by 2050 if no improvements are made in the sector.

Complexity of Recycling

Recycling is often complicated because post-consumer plastic waste often consists of mixed plastics of unspecified composition and often contains various contaminants, including organic and inorganic matter. Most of this plastic waste is either incinerated in power plants or discarded to landfills or oceans, resulting in a low or lost value. Single-use multilayer flexible packaging is a typical instance of such non-recyclable waste that ends up in landfills and, ultimately, in natural habitats. Approximately 8 million tons of plastics find their way into oceans per year and the plastic pollution in oceans is predicted to outweigh the oceanic fish by 2050. One-third of all plastic produced worldwide is too complex (e.g., complex structures, complex mixture of different polymers) or too small to recover or recycle in a practical and cost-effective method. Since plastic waste is largely chemically inert, estimates suggest that existing material would require around 250–500 years to completely degrade. Furthermore, the constituents of plastic waste can enter the human food chain through crops and animals. For example, crops might absorb and accumulate nanoplastics (e.g., dimensions < 6 nm)

Chemical Recycling, Upcycling and Downcycling

Plastics refining is a GHG intensive process. Carbon dioxide emissions from ethylene production are projected to increase by ~ 34% over the period 2015-30. For instance, PVC is an extensively used thermoplastic due to its excellent properties such as stability, being cheap, and workability. It is a multipurpose general plastic commonly used in construction, piping and many other consumer goods. PVC is highly polar and possesses a good insulation property, but it is inferior to other non-polar polymers like polypropylene (PP) and polyethylene (PE). PVC, PE and PP are usually used in piping, water sanity, and medical industries, etc. whereas PP is extremely thermally resistant, and it can withstand much higher temperatures than PVC. All these polymers including PET, nylon, and PU contribute to carbon footprint and global warming. PVC is demonstrated to have higher energy consumption and CO2 gas emissions which that show its high potential in global warming than other plastics. Likewise, the recycling of PVC has shown substantial contributions in lowering the effect on climate change.

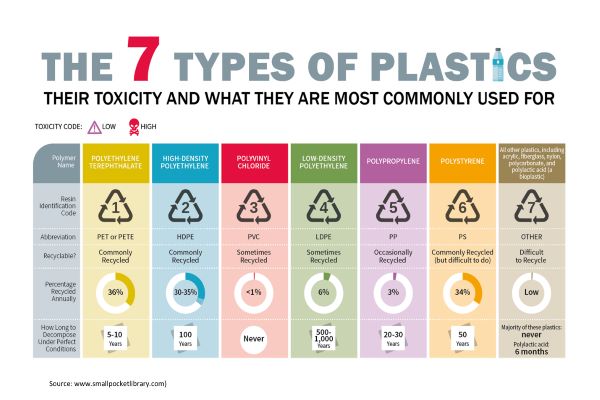

About 40% of plastics are used in packaging globally. Typically, packaging is meant for a single use (SUP) and therefore there is a reckless turnaround for disposal at all places. SUPs are used in many applications such as tires, fabrics, and coatings. Consumers need choices to avoid plastic waste such as legal means to encourage plastic collection through a refundable deposit scheme on SUPs, collection at regular intervals and avoiding plastic waste going as a mixture in municipal solid waste (MSW). The packaging can be dealt with in three different ways including landfill, incineration, or recycling. Waste incineration leads to the largest climate impact of these three options. According to the World Energy Council (WEC), based on the current trend in plastics production and incineration upsurge as anticipated, GHG will rise to 49 MMTA by 2030 and 91 MMTA by 2050. Landfilling has a much lesser impact on climate than incineration. But the landfill sites can be related with similar environmental issues. Recycling is a much better option. With regard to the little costs of virgin plastics, recycled plastics are high cost with low commercial value. It makes recycling lucrative only seldom, and so it calls for substantial subsidies by the government authorities. On the contrary, the chemical recycling of polymers including depolymerization and hydrogenation are excellent choices. Plastics can be categorized broadly into 7 types (See Figure 3):

Chemical or feedstock recycling is being touted as a game changer that can transform recycling. With chemical recycling, innovative technologies such as pyrolysis, gasification, chemical depolymerization, catalytic cracking and reforming, and hydrogenation convert plastic waste into chemicals. These technologies produce feedstocks such as monomers, oligomers, and higher hydrocarbons that can in turn be used to make virgin polymers. Green hydrogen will play an important role (Figure 4).

Use of hydrogen in plastic recycling

Hydrogenation (hydrocracking, hydrotreating, hydrogenolysis) of waste plastic is very useful to convert any plastic waste into hydrocarbons/oils useful as fuels and chemicals. Tough atoms such as, N, S, and Cl are easily broken and the technologies are well known in refinery and chemical industry (Figure 5). Green hydrogen will be the real saviour. Any mixed plastic can be catalytically converted into hydrocarbons for reuse as fuels or feedstock.

Figure 3. Different type of plastic waste and their impact on environment

Figure 4. Chemical recycling of waste plastics. Once the segregation is done at source, it becomes easy to chemically react waste plastic into a variety of products.

Providing Incentive for Collection of SUPs & Public Participation

Anything free, irrespective of cost, is not appreciated and thrown out as scrap, garbage or waste. Plastic packaging falls into this category. Collection of SUPs from the consumers can be advanced by levying refundable deposits which should be more than the cost of the article or product, properly labelled without causing additional pollutants; and thus, the consumer is disciplined and encouraged to return the used goods anywhere convenient to them. For instance, if a plastic straw, or PET bottle or milk pouch which may cost a few paise, is given to the customer for a refundable deposit at Rs. 5 per piece irrespective of size or thickness, they will return it to collect their deposit. Or if somebody else (just not rag pickers but others in offices and functions) collects it, they are encouraged to return and collect the deposit. Here to reduce the burden, all articles irrespective of size or weight can be returned. Like the newspaper boy coming to the doorstep, another plastic collector will come to collect the segregated clean plastic from each house, deduce his fee/commission (e.g. 5%) and refund the remaining deposit. It can be done digitally through bar codes which can be used only once to collect the deposit anywhere in India. It will promote digital economy. Like the education cess, government has already introduced the Swachh Bharat cess which is supposed to be used to deal with all plastic goods lying around in colonies. One of the mistakes done by authorities is that the plastic waste should be collected at a decent price so that rag pickers pick up all plastic bags and ‘useless’ articles rather than only the PET bottles which they choose from the garbage and are recycled.

Future of Recycled Plastics

The new paradigms are Waste to Wealth, Circular Economy and Renewable Energy, particularly solar, wind and green hydrogen. Recycle Engineering, Process Intensification, Waste Minimization and Green Processes must be practiced for achieving sustainability. There is a big concern that enormous quantities of plastic waste being incinerated and discharged into the landfills and the environment, there is a tremendous scope for further upgrades in the management of waste plastics, especially through chemical recycling which concerned with thermal pyrolysis, solvolysis, in-situ/ex-situ catalytic pyrolysis, co-pyrolysis, hydroreforming, steam/ CO2 reforming of plastic pyrolysis volatiles and gasification and hydrogenation of waste plastic. When the crude oil resource is depleted and millions of tons of plastic is lying around, it will be prudent to use it as a feedstock. Chemical recycling is an excellent idea whose time has come. Catalytic processes to recycle or upcycle plastics will be hotly pursued. More research is needed on upcycling of thermosets. If government-established recycling targets are to be achieved, the links between consumers, municipalities, and petrochemical production must be improved. The Govt of India should not ban SUP but provide incentive to common citizens to return used articles, it will do wonders. After all, public opinion is moved by media images of a threatened planet and eco system. Only through the collaboration of people, municipalities, and industry - supported by improved technology along the recycled plastics supply chain a solution for this global crisis can be achieved.

The Govt. of India, I believe, ought to use some the ideas presented in my article which I have been talking about since 2018 in newspapers, articles and seminar (see YouTube) and should not ban SUP but incentivize the general public to be responsible.

Subscribe to our newsletter & stay updated.