The new collaboration will help to increase production of certified circular products that take used mixed plastics to make feedstock

bp and SABIC have signed a new agreement to work together to drive circular economy in the petrochemical activities at the Gelsenkirchen (Germany) chemical complex.

Building on a long established relationship between the two companies at the production site, the new collaboration will help to increase production of certified circular products that take used mixed plastics to make feedstock, thereby reducing the amount of fossil resources needed in the petrochemical plants at the site.

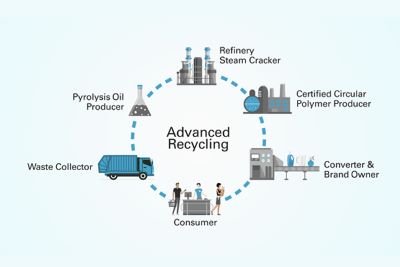

Certified circular polymers are part of SABIC’S TRUCIRCLE portfolio. The materials are produced using advanced recycling to convert low quality mixed and used plastic, otherwise destined for incineration or landfill, into pyrolysis oil. The oil, which acts as an alternative feedstock to traditional fossil materials, will be processed at bp’s Gelsenkirchen refining site and then used by SABIC in its Gelsenkirchen polymer plants to produce certified circular products.

The final material has identical properties to virgin-based polymers and allows plastics to be recycled over and over again, with no loss of properties or characteristics. After successful trials in December 2020, polymer production using the alternative feedstock started at the site early this year.

“SABIC is committed to helping create a new circular economy where plastic never becomes waste,” said Fahad Al Swailem, Vice President, PE and Sales at SABIC. “Advanced recycling has a crucial role to play in the current recycling mix as it can capture value from plastic waste streams that have traditionally been ignored or discarded. We continue to increase our collaborations with upstream suppliers and downstream customers, and this new initiative with our long-term partner BP takes us one step further to achieving our vision.”

Wolfgang Stückle, Vice President, Refining and Specialties Solutions Europe & Africa at BP, commented: “This is an important milestone in our vision of achieving up to 30% of our ethylene and propylene production from sustainable, recyclable raw materials by 2030. It is a fantastic achievement on the part of the Gelsenkirchen team, after more than a year’s preparation, to set up the new initiative with our partners at SABIC. At the same time, it is what BP’s recently announced Net Zero strategy is all about.”

The certified base chemicals from bp and the certified circular polymers from SABIC are recognised through the International Sustainability and Carbon Certification plus (ISCC+) scheme that certifies content and standards across the value chain from source to end product. The ISCC+ certification works on what is known as a ‘mass balance system’, meaning that for each tonne of circular feedstock fed into the cracker and substituting fossil-based feedstock, a tonne of the output can be classified as circular.

Subscribe to our newsletter & stay updated.