Continuous process optimization driven by real-time sensor-based machine, mold and material data

NETZSCH Process Intelligence, a corporate venture of NETZSCH Group (Germany), has announced the launch of sensXPERT, a technology business designed to deliver significant productivity and quality benefits to processors in the plastics industry through data-driven manufacturing solutions. The integrated approach builds on the Group’s 50+ years of know-how in the fields of material science and sensor technology.

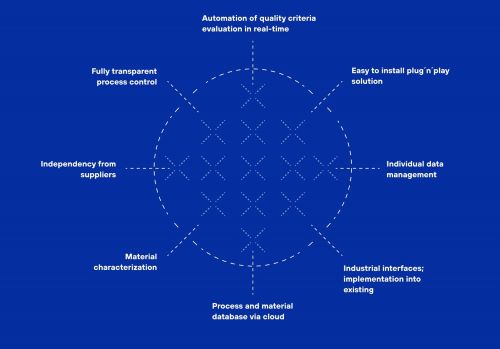

sensXPERT combines real-time material data from the mold with advanced machine learning software to analyze the material behavior. The smart technology enables continuous process optimization for up to 30 percent increase in production efficiency. Its technological advanced in-mold sensors provide real-time insights and transparency to react to material deviations and eliminate scrap. While allowing a dynamic and adaptive production, thus maximizing throughput, sensXPERT ensures direct in-process quality control of each single molded part.

“There is a growing need for digital technology solutions in the plastics processing industry to meet the challenges of tighter cost control, total quality assurance and enhanced sustainability,” says Dr. Alexander Chaloupka, Managing Director & CTO for sensXPERT. “By using the artificial intelligence of our machine learning software to evaluate critical material, machine and process data, we help our customers optimize their manufacturing efficiency in real time, eliminating the need for time and labor consuming retroactive adjustments.”

sensXPERT lives a 'customer-centric' approach enabling plastic processors to have full manufacturing transparency. Next to seamless third-party sensor integrations, the company realized the potential to further link and connect production machines and molds with material science. The result is an exponential output increase that is immediately utilizable. True to the sensXPERT motto: Turning data into quality!

“Industry 4.0 stakeholders need real-time answers to what is happening in their manufacturing processes,” adds Cornelia Beyer, Managing Director & CEO of sensXPERT. “Our unique approach unlocks the potential of fully data-driven productivity, delivering immediate quality and efficiency benefits to our customers in the plastics processing industry.”

Subscribe to our newsletter & stay updated.