The product is well-suited for large-volume applications that require substantial amounts of adhesives or sealants

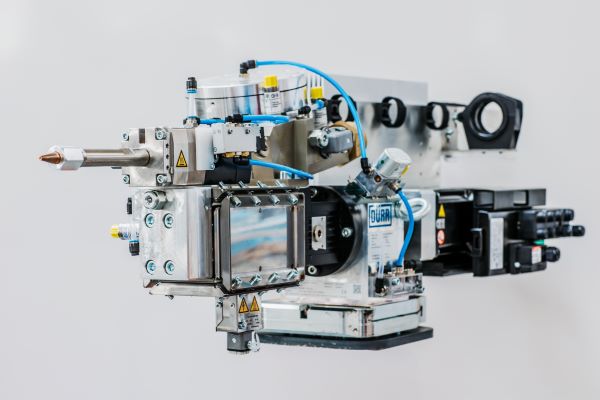

Dürr expands its product line with the EcoMeter SP, a continuous dosing system designed for the seamless application of highly viscous media without interrupting material flow.

This product is well-suited for large-volume applications that require substantial amounts of adhesives or sealants.

A screw spindle pump drives the continuous dosing system, making it lighter and more compact, lower maintenance, and more cost-effective than previous alternatives.

Three screw spindles deliver uninterrupted and continuous material feed. An electric servo motor drives the middle spindle, initiating movement in the other two. The connected supply station holds the material. These spindles rotate in opposition to push the material into the endless dosing system’s applicator. In contrast, piston dosing systems rely on material pressure to fill the chamber before the piston’s action expels it.

This repetitive piston movement interrupts the application process, potentially exceeding predefined cycle times. In addition, piston dosing systems’ maximum filling quantity limits their application range. Previously, users either purchased the biggest available model with a volume of 600 cubic centimeters or combined two smaller piston dosing systems with a volume of 150 or 300 cubic centimeters into a tandem dosing system to counter this disadvantage.

This tandem solution was the only option for continuous material flow using the proven piston dosing technology.

In contrast, the EcoMeter SP offers unlimited capacity making it versatile. It is suitable for countless application processes in car manufacturing, including body-in-white construction, final assembly, and battery manufacturing. It offers additional benefits besides endless dosing. The absence of a reverse piston stroke reduces cycle times, increasing production capacity. Compared to a tandem solution using two-piston dosing systems, employing a single spindle reduces the dosing system’s overall weight by up to 20 percent and its required installation space.

This makes the EcoMeter SP more agile and dynamic, and it can connect to smaller robot arms. Moreover, the EcoMeter SP’s maintenance is less complicated with just one seal for material feed. The dosing system also uses less energy and is up to 40 percent cheaper than the comparable tandem version with piston dosing technology.

Dürr is offering the EcoMeter SP not as a replacement but as a complementary addition to the proven EcoShotMeter models with piston drive, which are ideal for applications that require high pressure, high volumetric flows, and utmost precision.

Subscribe to our newsletter & stay updated.