Experts decode how AI, automation, and connected ecosystems are reshaping process R&D with speed, precision, and collaboration at the core

As industries strive to stay ahead in an increasingly competitive landscape, digital transformation has become the strategic imperative driving the next wave of breakthroughs in process R&D. By integrating advanced technologies such as AI, data analytics, automation, and digital twins, companies are unlocking new levels of agility, efficiency, and innovation. This shift is not just enhancing productivity but reshaping how scientists design, test, and optimize processes, making R&D smarter, faster, and more resilient to disruption.

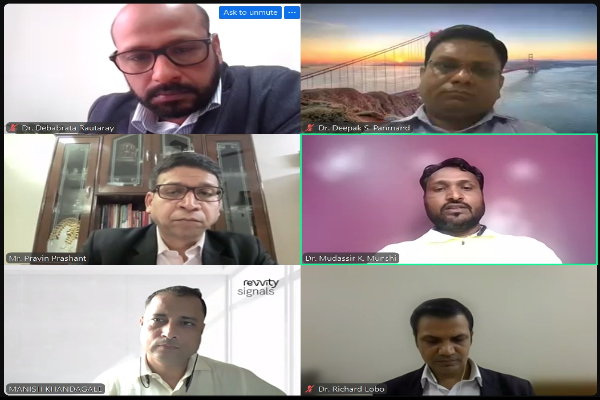

In this context, an e-conference on the topic, ‘Digital Transformation: The Catalyst for Agile and Smarter Process R&D’ was organised by the Indian Chemical News on June 4, 2025 in association with Revvity Signals. The discussion was moderated by Pravin Prashant, Executive Editor, Indian Chemical News.

Dr Manish M. Khandagale, Senior Field Application Specialist, Revvity Signals emphasized the need for a seamlessly connected ecosystem to enhance R&D efficiency. “When we look at any R&D process as a cycle of design and need for identifying challenges, we need to have a connected ecosystem where data flows smoothly. Whether it is decision making, excellent execution, you need to ensure data flows smoothly by identifying the key bottlenecks such as data capture and accessing it, collaboration issues, and repetitive tasks which consume a lot of time. So we need to see how we can address most of these challenges by using digital transformation and whether we can standardise the data capture and have an automation system with direct automation communication with systems to eliminate the unwanted or repetitive tasks. We have to look at the systems which are critical such as ones with front charts or some other analysis that could be looped in with each other. We can have a connected ecosystem where everyone can access the data, helping them to accelerate their processes. In terms of growing complexity of molecule research in multi-disciplinary workflows, there are many approaches. Sometimes it is a multimeter process and a few times it is the synthesis process. To handle all this, you need software which can provide you with intelligent solutions. For example, if you have a platform that can connect to request synthesis or do predictions so that you can build a list. So again it will require you to connect with different databases. You have to support the process of a new word with probability of different departments or even geographies. So, we need a solution which can share all this information without risking your IP and compliance.”

Dr Debabrata Rautaray, Vice President and Chief Product Development & Innovation Officer, DCM Shriram Chemicals Innovation Centre highlighted the fragmentation of knowledge and processes during new product development as a persistent challenge in specialty chemicals R&D. “One of the most common issues we face is disconnected workflows. Experiments are often noted on blackboards, while ideas are exchanged through emails, paper charts, or informal discussions. This scattered approach increases the risk of losing valuable insights, especially when team members move on or when projects are handed over. In such a scenario, the digital transformation has helped solve this problem. We have a lot of initiatives in this particular space such as connecting all our research activities into easy to use systems. We have used Revvity’s electronic lab notebooks where our researchers maintain handwritten notes, they can login their experiments online, which means the data they can search at any point of time safely and it can be instantly shared with their colleagues irrespective of the location. Similarly, there are many tools where chemists can draw their structures and also internally you can have online data generation platforms where anyone in the R&D, sales or marketing can contribute ideas and these can be reviewed, rated and tracked. The person who was given the idea remains recorded in the system. Other digital tools help in searching literature online and patent analysis tools that help researchers. For example if they are looking at developing a specific molecule, one can quickly check if there are new ideas, truly unique or somebody has already done it, saving a lot of time. The biggest challenge is that there is a lot of documentation and to ensure that these processes are most streamlined and easy to use, we are trying to develop online systems where there are no repetitions and make the life easier for scientists. Overall, the digital tools help us in cutting down a lot of confusion and delays in the projects for all the stakeholders involved. They actually help in reducing experimental time and make our work smarter, faster and more reliable.”

Dr Mudassir K. Munshi, Team Leader, Deepak Nitrite emphasized that digital transformation is no longer just a trend but an essential requirement for the chemical industry: “At its core, digital transformation is about enhancing our existing systems, particularly data management, by integrating AI-powered tools into conventional R&D workflows. Fundamentally, it will be enhancing our ongoing activities such as data management system by clubbing the AI powered tool to conventional processes. I believe a lot of digital tools we have been using already if clubbed with AI will give further optimal experimental conditions based on historical data and reduce the error. The digital transformations in terms of augmenting the data capture as an electronic system is an important tool. Having the right electronic notebook is very crucial. For example, there are various kinds of processes that need special attention in order to have the data function as per the process requirement. One such data electronic electronic system is also developed here at Deepak Group and we have been using this for a decade. It is a fantastic product not just for internal use but also available as a product. We have customized this according to the various types of the processes in the industry, whether it is commodity chemical, agrochemical or pharmaceutical. The moment we change the type of a process, the capturing of information has to be not only at the development stage but also right from the realization of the project. If we have this kind of mindset, we will corporate all those needs to the software development, and he can come up with the right kind of information in the form of an electronic notebook to contain the processes, like the conventional backward process. On the continuous processes, we need to have the different platforms in the same electronic notebook so that we can capture the information accordingly. We have to also ensure that within the same project, for maintenance you can access the information as and when it is required from historical data as we need not reinvent the wheel. We could also be able to incorporate the search engine in the electronic notebook to get the data right from the feasibility stage, the information that has been gathered to develop the process. I believe we can in a parallel way do the test of what we have developed in the software and redefine our workflow. That ways we can take back the test to execution”

Dr. Richard Lobo, Global Head Business Excellence, Innovation, R&D | Chief Ethics Counselor, Tata Chemicals underscored the multifaceted challenges facing the R&D ecosystem today: “The R&D community faces a number of challenges, starting with the complexity of discovery itself as identifying new molecules, materials or technologies is very uncertain and very time consuming. Data, and then the opinion overload on that data is the next issue that always happens. Then there are regulatory compliance that you need to do and some of them are very lengthy. Be it pharma, biotech and even agrochemicals in India that can take anywhere between 5-8 years to get regulatory clearances. Then there are data integrity requirements. For example, traceability, audits and filing patterns. There are many challenges globally but at the top are financial and resource constraints. R&D which is a deeply expensive, resource intensive approach and you need to have radical innovation and not just incremental innovations. While you can get so many of these issues addressed and now even easier with digital tools. I think that shift is happening now. At Tata Chemicals, we have hybrid agriculture seeds and it takes 4-6 years through molecular breeding because we are not permitted to do genetic modifications in India. Through the molecule breeding, you get the best resistance, lower water consumption, better nutrients in the seeds. The power of Gen AI was used on 2000 traits to bring them down to 20. We got about 95% accuracy and dropped the cycle time to just about a few months. Gen AI in many ways is crushing discovery timelines. I think it's very important now to have a portfolio management approach to high impact projects. I think it was excellent in terms of managing R&D projects and then bringing it to portfolio management to address the innovativeness. The ability to have open innovation, crowdsourcing models, public private partnerships and grants so that your financial and resource constraints get rapidly addressed. And finally, what's very important for the scientific community is finding ways to do rapid R&D prototyping because while we can spend a good many years trying to get the right innovation to market over the hurdles of regulation, getting the data, doing the analysis, getting the approvals. If you don't rapidly prototype this to market quicker, we will not be able to understand whether it is fit for purpose, whether it can scale in the market, and digital tools will allow us to predict it faster.”

Dr Deepak S Panmand, General Manager (R&D), Dhanuka Agritech highlighted the unique challenges faced by the agrochemical process industry, where unpredictability in climatic conditions and rapidly mutating pests intensify the pressure on R&D teams to develop timely and cost-effective pesticide solutions. He explained: “Agrochemical process industry is majorly dependent on the climatic conditions as it is unpredictable. The pests have fast mutations due to cost resistance, putting pressure on the R&D teams to find and develop cost effective pesticide solutions. In the product development cycle, there is a need for selecting the right molecule for R&D, we need to have the information such as manufacturing company, supplier details, export data etc. 90% of this information is available on the websites but when the molecule gets into the laboratory for development, there are multiple questions before process chemists such as patent availability status of the molecule, data safety, compliances. Till date we are working in digital mode and whatever data is randomly available is scattered. A lot of time gets consumed in putting this data at one place and leads to loss of time. By centralizing and organizing critical data in a single digital interface, chemists can make faster, more informed decisions. This not only accelerates the product development cycle but also helps reduce costs, minimize environmental risks, and significantly cut down on avoidable wastage. The digital transformation in terms of most of the information available at one place helps the organic chemist to make the right decision and develop the product in a cost effective manner. A lot of information is provided in a short period of time, thus helping to make quick decisions, saving a lot of time and reducing wastage without any environmental hazards.”

Subscribe to our newsletter & stay updated.