Neeraj Tiwari, Senior Technical Advisor, Design and Engineering, Jubilant Ingrevia; Amish Jani, CoE Corrosion Engineering – Static Equipment Reliability, Reliance Corporate Park; Prashant Bhurrak, GM - Mechanical Design, Aarti Industries; Urvesh Vala, Head, Material Engineering Technology, L&T Energy Hydrocarbon Engineering; Aditya Sheth, MD, Galiakotwala Engineering Company; Paresh Haribhakti, MD, TCR Advanced Engineering; and Sudhindra Hathwar, Business Development Manager, Alleima are speakers for the session

Indian Chemical News (ICN) in association with Alleima (formerly Sandvik Materials Technology) is organizing a session on "Combating Heat Exchanger Tube Corrosion in Chemical Industry" on August 25, 2023 at Hotel Hyatt Place in Bharuch. The main theme of the event is "Combating Heat Exchanger Corrosion in Chemical Industry."

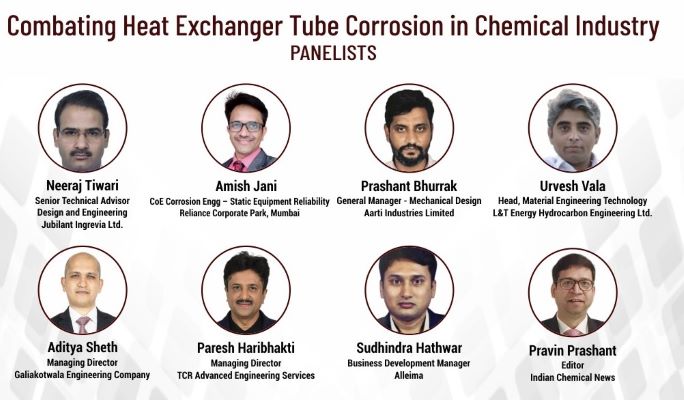

The speakers for the session are: Neeraj Tiwari, Senior Technical Advisor, Design and Engineering, Jubilant Ingrevia; Amish Jani, CoE Corrosion Engineering – Static Equipment Reliability, Reliance Corporate Park; Prashant Bhurrak, General Manager - Mechanical Design, Aarti Industries; Urvesh Vala, Head, Material Engineering Technology, L&T Energy Hydrocarbon Engineering; Aditya Sheth, Managing Director, Galiakotwala Engineering Company; Paresh Haribhakti, Managing Director, TCR Advanced Engineering; and Sudhindra Hathwar, Business Development Manager, Alleima are speakers for the session. The moderator of the panel discussion is Pravin Prashant, Editor, Indian Chemical News.

The Indian Chemical industry is expected to rise from around US $180 billion in 2021 to US $850 billion to US $1,000 billion by 2040. The industry is projected to grow 11 to 12 percent during 2021–27 and 7 to 10 percent during 2027-40, thereby tripling its global market share by 2040. This growth is expected to be driven by the rising domestic consumption and expanding product basket.

Heat exchanger tube corrosion is a major problem for plants across all industries. It not only impacts the plant's operational efficiency but also increases operating costs for the plant. Hence, it is important to have solutions to tackle the challenges of heat exchanger tube corrosion. Experts advise to select appropriate materials to ensure corrosion resistance in heat exchanger tubes. Materials such as stainless steel, titanium, and high nickel alloys can resist corrosion caused by chemicals. It is also important to have regular monitoring of heat exchanger tubes to detect corrosion at an early stage, chemical cleaning, passivation, temperature control, maintenance and corrosion inhibitors in place.

Key discussion points to be covered during the panel discussion are: Challenges in heat exchanger tubes; Types of corrosion failures or challenges; Industry expectations with respect to heat exchanger; Corrosion monitoring of heat exchanger tubes; Selecting appropriate materials for handling new product/molecules; and Showcasing “Model of cost saving by using better material”.

Subscribe to our newsletter & stay updated.