Accelerating technological development and open innovation under NEDO’s Green Innovation Fund project

Sojitz Corporation, Central Research Institute of Electric Power Industry, Green Earth Institute Co., Ltd., DIC Corporation, Toray Industries, Inc., and Daicel Corporation, have concluded an agreement with Japan’s New Energy and Industrial Technology Development Organization (NEDO) for a joint project focused on the development of revolutionary biomanufacturing technology to engineer hydrogen oxidizing bacteria that utilize CO2. This project was selected for sponsorship under NEDO’s Green Innovation Fund Project category, “Promotion of Carbon Recycling Using CO2 from Biomanufacturing Technology as a Direct Raw Material.”

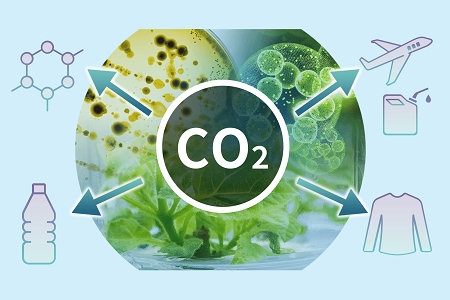

This project entails R&D for manufacturing a variety of chemical products and feed raw materials from CO2 and H2. This new biomanufacturing technology will be the world’s first example of a commercialized bioprocess directly using CO2 and H2 for productions of chemicals and presents a promising option for realizing a carbon neutral society.

The hydrogen-oxidizing bacterium*¹ to be engineered is one of microorganisms that have fastest CO2 fixation rate. Leveraging this high fixation capacity through genetic engineering, it is possible to engineer bacterial strains that can produce useful chemical products with high efficiency. The resulting compounds are then used as raw materials in a wide variety of daily applications including plastics, ink, paint, textiles, and cosmetics. Additionally, the bacterial residues produced in the biomanufacturing process from the biomanufacturing process can be utilized as an alternative protein source for feed which presents a solution to the recent rise in demand for alternative protein sources. This biomanufacturing technology will therefore simultaneously raise the decarbonization value of businesses and provide a solution to food problems.

Alongside the development of bacterial strains, scale-up demonstrations will be conducted to establish a safe and highly efficient gas fermentation method and to accurately measure CO2 reduction effects to add environmental benefits to products.

All six organizations will combine their acquired expertise, technologies, and functions to realize social implementation of this next generation biomanufacturing technology in order to advance the structural transformation of chemical products and materials industries which address growing decarbonization needs.

Subscribe to our newsletter & stay updated.