100 percent substitution of fossil feedstock with bio-circular raw material from waste cooking oil

Evonik is driving circular plastics economy in additive manufacturing. The leading specialty chemicals company is introducing a new grade of its polyamide 12 powders that is designed to unbound sustainable 3D printing at scale.

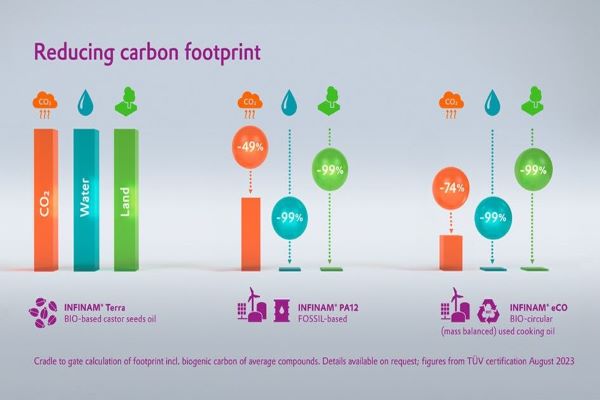

INFINAM eCO PA12 is the world’s first PA12 powder material for industrial 3D printing that substitutes 100 percent of fossil feedstock with bio-circular raw material from waste cooking oil in a mass balancing process. The new, ready-to-use powder features a reduction of CO2 emissions of 74 percent in comparison to the castor oil-based polyamides of Evonik's own INFINAM® Terra development grade. Having already launched a new PA12 grade with reduced carbon footprint in late 2022, Evonik is now fully aligning its portfolio of polyamide 12 powders with its circularity approach. Evonik will present its formula to drive circular plastics economy in 3D printing during the Formnext trade show, Frankfurt am Main Germany, November 7-10, 2023.

True circularity starts with bio-circular raw materials. More than 15 million tonnes of waste cooking oils are produced annually in the world by restaurants, grocers, hotels and casinos, and other foodservice providers. In addition to other end-of-life possibilities like being processed into biodiesel, waste cooking oil can be used as raw material source for chemical production.

“True circularity is key for being successful in the future. As a pioneer for polymer-based 3D printing materials, Evonik has developed a formula for its PA12 powders to drive circular plastics economy in additive manufacturing”, says Dominic Störkle, Head of the Additive Manufacturing Innovation Growth Field at Evonik. “With the introduction of INFINAM® eCO PA12, we go far beyond chemistry to start closing the loop, and meet the market’s expectations for a better future.”

INFINAM eCO PA12 contributes to both footprint and handprint circular values. Besides an improved carbon footprint rate due to renewable energy use for production and bio-circular raw material, Evonik’s new polyamide 12 grade provides proven reusability rate of 100 percent of the structure support powder, with a refresh rate of 70/30 of used versus virgin material over several printing cycles, all the while exhibiting excellent processability and stable mechanical properties of 3D printed parts.

Subscribe to our newsletter & stay updated.