Ambani said that Oil-to-Chemicals (O2C) business is well on its way to achieve net carbon zero by 2035 through the use of renewables and bioenergy

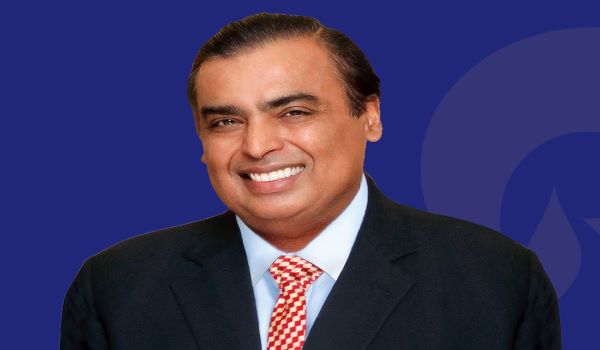

Reliance Industries Limited (RIL) Chairman Mukesh Ambani in the 46th AGM announced plans for the company on Oil-to-Chemicals, gas, CBG plants, green hydrogen, new energy, battery giga factory and other business verticals.

On Oil to Chemicals (O2C)

In the year gone by, our Oil-to-Chemicals (O2C) business operated in a highly volatile global scenario. Despite all the challenges and a new one-time tax in the form of Special Additional Excise Duty (SAED), our O2C EBITDA for FY23 improved by 17.7% to a record high of Rs 62,075 crore.

Our asset utilisation remained higher than the industry average through robust planning and exceptional teamwork. We operated with the lowest level of feedstock inventory in our history to benefit from opportunities in a turbulent global oil market. Fully utilising the flexibility and integration of our assets, we added 13 new grades of crude oil and feedstocks.

We ensured high availability of the Gasification unit to minimize the purchase of high-cost LNG to lower our energy costs. Our partnership with bp in fuel retailing and mobility solutions continued to make steady progress.

We have embarked on our journey to transition our O2C business into a sustainable and green, circular and consumer-integrated, chemicals and materials business.

The key pillars of this transition are -

* We are accelerating e our journey to achieve Net Zero by 2035 through use of renewables and bioenergy for a sustainable and green business. We are well on our way to build the New Energy ecosystem of manufacturing solar, wind, batteries, hydrogen, and bioenergy platforms. This will enable us to speed up development of our renewable generation assets to deliver round-the-clock electricity for our captive requirements as well as to meet the growing needs of Indian consumers. As the cost of renewables will be significantly lower compared to fossil fuel-based energy, this will result in reduced energy costs and improved profitability for the O2C business.

* We are accelerating Circularity and Consumer-integration. We have also been working on scaling up our chemical recycling technology to deliver application-specific green products. This is helping us access high value, high potential customers in new value chains.

* With technology and innovation, our Refinery at Jamnagar will be progressively operated as a ‘Chemicals and Materials Feedstock Production’ engine. We started this by converting some low-value refinery streams to recently launched highly specialized Halo-Butyl Rubber grades and a new Purified Isophthalic Acid Plant, which is under commissioning.

On Battery Giga Factory

Our concurrent priority is to set up our battery giga factory by 2026. It will manufacture battery chemicals, cells and packs, leading all the way up to containerised energy storage solutions, and will include a battery recycling facility to deliver a truly integrated ecosystem.

We will start with LFP chemistry which has been proven at scale for its safety, stability, and life, targeting to produce LFP based solutions at world beating lifecycle costs.

Simultaneously, we are focused on fast-track commercialisation of our sodium ion battery technology. We will build on our technology leadership position by industrialising sodium ion cell production at megawatt level by 2025, and rapidly scale up to giga scale thereafter.

On Carbon Fibre

We are executing India’s first and world-class Carbon Fibre facility in Hazira, Gujarat. Our Carbon Fibre platform will include Carbon Fibre and Carbon Fibre Reinforced Plastics. Our target is to be among the top three players globally in the Carbon Fibre and Carbon Fibre Reinforced Plastic composites.

On Gas

We are well on our way to enhance production to 30 MMSCMD, which will be 30% of India’s gas production and 15% of its current gas demand. This gas is a major source of clean energy saving up to $7 billion per annum in imports for the country. Gas is a key transition fuel in our nation’s quest for clean and sustainable energy. With our valued partner bp, we have revived gas production from KGD6 Block from near zero a few years back to about 20 MMSCMD in FY23.

On CBG Plants

India produces nearly 230 million tonnes of non-cattle feed biomass, most of it contributing to air pollution. Within a short span of one year, we have become India’s largest Bio-Energy producer based on our indigenously developed technology.

After setting up two demo units for Compressed Biogas (CBG) at Jamnagar, we have commissioned the first commercial scale CBG plant at Barabanki in UP in a record time of just 10 months. We will rapidly scale this up to 25 CBG plants across India. Our target is to establish 100 such CBG plants in the next 5 years, consuming 5.5 million tonnes of agro-residue and organic waste, thereby mitigating nearly 2 million tonnes of carbon emissions, and producing 2.5 million tonnes of organic manure annually. This would result in a reduction of about 0.7 MMTPA of imported LNG.

We will also pursue Wind Power generation. Towards this, we have made significant progress in developing a manufacturing ecosystem critical to achieving cost-efficient Wind Power generation at giga scale.

On New Energy

We are progressing well to deploy our committed capital of Rs 75,000 crore to build our New Energy manufacturing ecosystem. This will enable us to accelerate giga-scale production for round-the-clock power and for large-scale Green Hydrogen production for green chemicals manufacturing, as well as for green mobility.

We will continue to invest in technology, and talent. We will collaborate with global technology and product companies including start-ups focused on commercialising emerging and disruptive technologies. We are rapidly adding to our rich talent pool of several thousand scientists, engineers, and innovators, drawn from countries around the world.

Our transition to Net Zero and building a sustainable chemicals business will result in increased revenue, reduced energy costs, improved profitability, and providing a near perennial growth platform in India and overseas for our Materials and Energy Business.

We remain focused on fast-track execution of our Dhirubhai Ambani Green Energy Giga Manufacturing Complex at Jamnagar. Our first priority is to deliver a fully integrated, end-to-end solar PV manufacturing ecosystem. This will be one of the largest, most technologically advanced, flexible, and most cost-competitive solar giga factory globally, and we will be converting sand into solar PV modules.

Our solar giga factory will include manufacturing of PV Modules, Cells, Wafers and Ingots, Polysilicon, and Glass at a single location in Jamnagar. We will target to bring the factory on-stream in a phased manner by the end 2025.

We will be deploying leading-edge Heterojunction technology for manufacturing one of the highest efficiency solar PV cells and modules globally, for utility scale and rooftop power generation. We will further continue to innovate and maintain global leadership.

We will further leverage our engineering and construction capabilities, along with our giga-scale manufacturing ecosystem, to accelerate and enable installation of at least 100 GW of renewable energy generation by 2030.

On Green Hydrogen

During the last AGM, we were still working on two critical components for delivering most cost competitive Green Hydrogen and its derivatives – cost of renewable power generation, and installed cost of electrolyser for giga-scale deployment. Our solar and wind energy storage integrated manufacturing ecosystem will deliver the most cost-efficient renewable power. I can also confidently now say that we have a roadmap towards achieving our targeted cost of electrolysers, and in turn, Green Hydrogen.

In collaboration with our technology partners, we are firmly on our way to successfully demonstrate this first at MW scale. We will leverage our engineering capabilities, large-scale manufacturing, and localization to optimize this at giga scale.

In parallel, we will set up a fully integrated, automated giga-scale electrolyser manufacturing facility. This will enable us to establish large-scale Green Hydrogen production at Jamnagar, gradually transition our captive requirements, and simultaneously integrate with Green Ammonia and Green Methanol production for domestic and international markets.

Subscribe to our newsletter & stay updated.