The sustainability roadmap of Indian Chemical Industries highlights the need for the industry to move towards more sustainable practices in order to reduce its impact on the environment and society.

Sustainability has become an increasingly important concern for businesses worldwide, as stakeholders demand greater accountability for the environmental, social, and economic impacts of industrial activities. The chemical industry is no exception to this trend, and Indian chemical companies are now taking steps to adopt more sustainable practices.

This article will outline a sustainability roadmap for Indian chemical industries. It will begin by discussing the current state of sustainability in the Indian chemical industry and the challenges faced by the industry. It will then move on to outline a roadmap that will help the Indian chemical industry to achieve sustainability targets.

1.0 Current State of Sustainability in the Indian Chemical Industry

India's chemical industry has significant importance in the country's economy. It contributes to approximately 3% of India's GDP and is projected to reach $304 billion by 2025. However, the industry also has significant environmental implications due to the use of toxic chemicals, water consumption, and greenhouse gas emissions. Therefore, it is essential to develop a sustainability roadmap for the Indian chemical industry that will enable it to grow while minimizing its environmental impact.

Currently, the Indian chemical industry faces several sustainability challenges. Firstly, the industry is highly energy-intensive, with around 12-15% of the total energy consumption in the country attributed to the chemical industry. This high energy consumption results in significant greenhouse gas emissions, contributing to climate change.

Secondly, the chemical industry is one of the largest water consumers in India, with around 20% of the total industrial water consumption attributed to the sector. This high water consumption puts pressure on scarce water resources, leading to water scarcity in some regions.

Thirdly, the chemical industry produces large amounts of hazardous waste and emissions, which can cause serious environmental and health problems if not managed properly. The industry is also vulnerable to accidents and incidents, such as leaks, spills, and explosions, which can cause significant damage to the environment and human health.

Finally, the industry faces social sustainability challenges, such as poor working conditions, low wages, and human rights violations, particularly in the case of contract workers.

2.0 Roadmap for Achieving Sustainability in the Indian Chemical Industry

Given the challenges faced by the Indian chemical industry, it is essential to develop a sustainability roadmap that will enable the industry to grow sustainably. The Indian chemical industry needs to adopt a comprehensive sustainability roadmap. This roadmap should include the following key elements:

2.1 Energy Efficiency and Renewable Energy

Improving energy efficiency is a key priority for the Indian chemical industry, as it can reduce greenhouse gas emissions and energy costs. The industry can achieve energy efficiency by adopting technologies such as energy-efficient boilers, heat recovery systems, and process optimization. The industry can also shift towards renewable energy sources, such as solar, wind, and biomass, to reduce its reliance on fossil fuels.

2.2 Water Conservation and Management

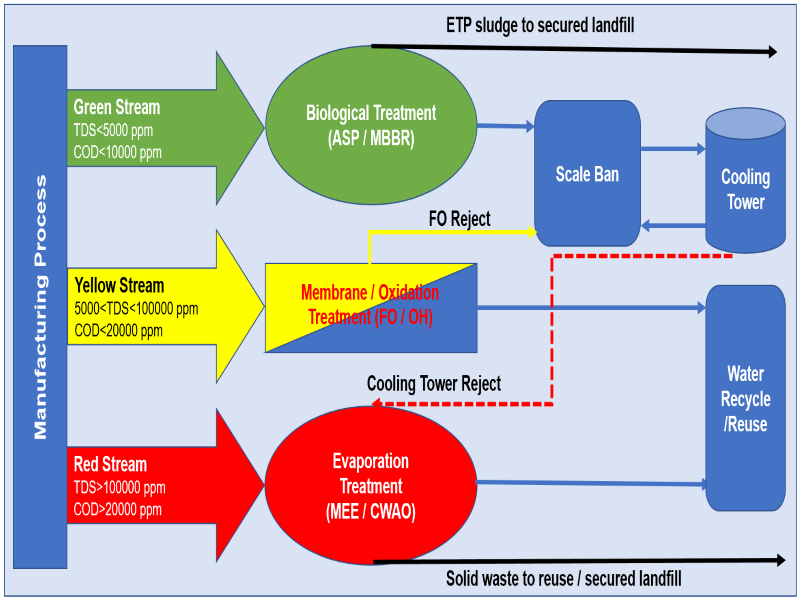

Water conservation and management are critical for the Indian chemical industry, as water scarcity is a major issue in the country. For sustainable wastewater treatment of a complex wastewater inside larger industrial plant, effluent characterization and stream segregation plays a vital role. The wastewater from the manufacturing process is segregated into 3 streams for easier and more efficient ways of achieving sustainable treatment. The 3 streams are:

O Green Stream

O Yellow Stream

O Red Stream.

In the green stream, the effluents have a TDS below 5000 ppm and a COD less than 10000 ppm, and after this is segregated it is sent for biological treatment, which is either activated sludge process technology (ASP) or the moving bed bioreactor technology (MBBR) for appropriate treatment. Then the treated effluent is sent to the scaleban which can then be a utilized in the cooling towers.

In the yellow stream, the effluents have a TDS below 100000 ppm, and higher than 5000 ppm whereas the COD is below 20000 ppm. This effluent is sent to either forward osmosis or the OH Radical where advanced membrane or advanced oxidation technology is used. Usually, ten percent of the effluent generated is rejected and is sent to the scaleban which can also be utilized in the cooling towers whereas the rest ninety present that is generated is clean water that can be used for other purposes at the plant or can be moved for water recycle or reuse.

In the red stream, the high polluting, high COD, and high TDS effluents get generated, and hence it’s low in amounts. This effluent is then channelized for Multi Effect Evaporation (MEE) and then sent for recycling or reuse.

The ETP Sludge and the solid waste produced throughout this process is sent to secured landfills thus making this process sustainable for use.

The sustainable treatment scheme inside large complex is shown in below figure 1.

This form of treatment is very relevant since the effluents are segregated into streams which leads to easier, efficient, and sustainable treatment of effluents. Usually, 60 percent is segregated into the Green Stream, 30 percent into the Yellow Stream, and 10 percent into the Red Stream, but this can vary from one industry to another.

The main logic of this form of treatment is that even though the effluents in the Red Stream are very less in amounts yet they are the most polluting and if they are not segregated then they mix with the other effluents causing extreme pollution throughout the system which is not favorable. Hence, segregation is of utmost importance and should always be considered when treating effluents.

The application of relevant technologies is also as important as segregation. As mentioned above, treatments like ASP and MBBR in the Green Stream, Forward Osmosis and OH Radical in the Yellow Stream and Multi Effect Evaporation (MEE) in the Red Stream lead to desirable outcomes.

Thus, this form of technology should be taken into consideration by companies as it’s not only efficient but also sustainable in nature.

Figure 1: Sustainable wastewater treatment scheme inside large chemical complex

2.3 Sustainability Management Frameworks

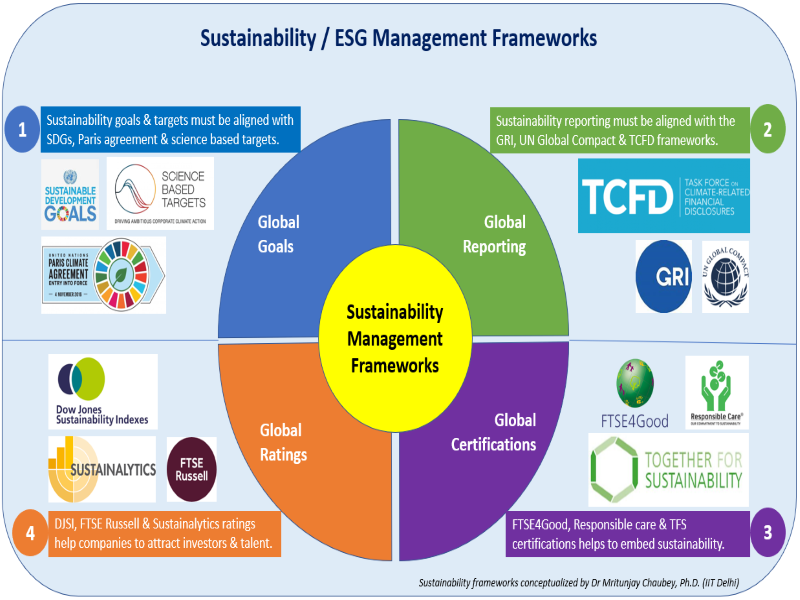

The Indian chemical industry needs to adopt a sustainability management framework to transform into 1.5 degree Celsius World. Chemical industries need to adopt structured approach towards sustainability. Following four approach must be adopted to embed sustainability in chemical industries:

1. Sustainability goals & targets must be aligned with sustainable development goals (SDGs), Paris agreement & science based targets.

2. Sustainability reporting must be aligned with the Global Reporting Initiatives (GRI), UN Global Compact & Taskforce on Climate Related Financial Disclosures (TCFD) frameworks.

3. FTSE4Good, Responsible care & Together For Sustainability (TFS) certifications.

4. Dow Jones Sustainability Index (DJSI), FTSE Russell & Sustainalytics ratings.

Conclusions

The sustainability roadmap of Indian Chemical Industries highlights the need for the industry to move towards more sustainable practices in order to reduce its impact on the environment and society. The roadmap provides a framework for the industry to adopt sustainable practices across its value chain, including raw material sourcing, production, transportation, distribution, and disposal.

One of the key conclusions of the sustainability roadmap is the need for Indian Chemical Industries to adopt cleaner production methods and technologies to reduce their greenhouse gas emissions, energy consumption, and waste generation. This can be achieved through the implementation of energy-efficient technologies, the use of renewable energy sources, and the adoption of circular economy practices. Another important conclusion of the sustainability roadmap is the need for Indian Chemical Industries to adopt responsible sourcing practices to ensure that their raw materials are sustainably sourced and do not contribute to deforestation or other environmental degradation. The industry should also work towards reducing its water consumption and improving its water use efficiency.

Overall, the sustainability roadmap provides a comprehensive and actionable framework for Indian Chemical Industries to adopt sustainable practices and contribute to a more sustainable future for India and the world.

Subscribe to our newsletter & stay updated.