Ammonia, a cornerstone of global industry, may be on the verge of a green revolution.

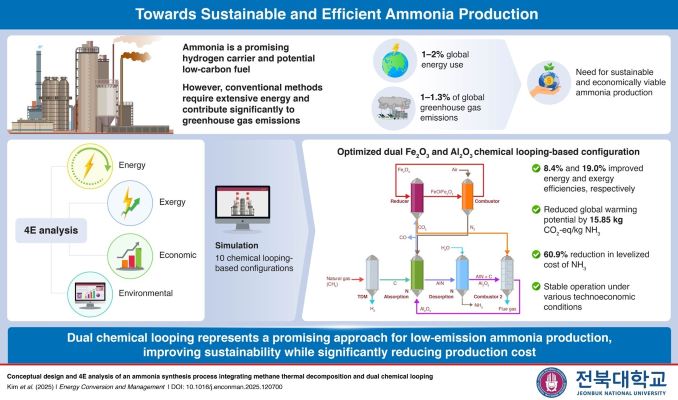

Traditionally used as a fertilizer, the chemical is also emerging as a promising low-carbon fuel and liquid hydrogen carrier. But conventional ammonia production via the energy-hungry Haber–Bosch process currently contributes roughly 1–1.3% of global greenhouse gas emissions each year, highlighting an urgent need for cleaner methods.

Now, a team led by Assistant Professor Sunghyun Cho at Jeonbuk National University in South Korea has developed a cutting-edge dual-chemical looping process that could dramatically reduce ammonia’s carbon footprint.

"Our approach combines methane thermal decomposition with Al2O3- and Fe2O3-based chemical looping cycles," Dr Cho explains. "This method enables ammonia synthesis without the energy-intensive steps, significantly improving both sustainability and efficiency."

The new process builds on recent advances in aluminium-oxide (Al2O3)-based chemical looping, which allows nitrogen fixation and hydrolysis under more energy-efficient conditions.

In the dual-loop system, thermal decomposition of methane supplies solid carbon, while an iron-oxide (Fe2O3) loop provides nitrogen, eliminating the need for energy-intensive air separation. Carbon monoxide generated within the Al2O3 loop is recycled as feedstock for the Fe2O3 system, creating a cross-linked circulation of key materials.

The research team tested 10 different configurations, including the dual-looping system, conventional Haber–Bosch, and single-loop alternatives.

Simulation results were striking: the dual-looping process outperformed conventional methods by 8.4% in energy efficiency and 19% in exergy efficiency, cut global warming potential by up to 15.85 kg of CO₂-equivalent per kilogram of ammonia, and offered the lowest production costs. Sensitivity analyses confirmed its robustness under varying technoeconomic conditions, and integrating heat exchangers further boosted efficiency.

"Our dual-looping technology can be applied across industries that require large-scale ammonia production while reducing carbon emissions and maintaining economic feasibility," Dr Cho concludes. "As the world moves toward cleaner energy systems, this process could support future clean-fuel applications and broader carbon-neutral energy-transition strategies."