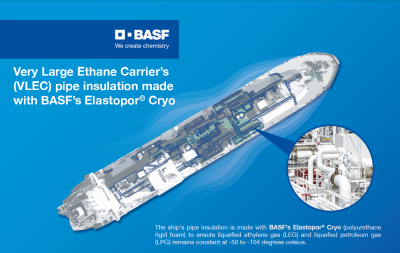

Cryogenic insulation system made with BASF’s Elastopor Cryo

A cryogenic insulation system made with BASF’s Elastopor Cryo by Shanghai Harvest Insulation Engineering Co., Ltd (Harvest), has been applied in the first VLEC (very large ethane carrier) delivered to Jiangnan shipyard, one of China’s leading shipbuilding companies. Elastopor’s excellent durability ensures the ship’s insulation capability even when subject to rough conditions at sea. As such, liquid cargo on the carrier can be maintained in a specific low-temperature state and be safely transported to land.

“In recent years, the LPG (Liquified Petroleum Gas) & LNG (Liquid Natural Gas) industries have been experiencing strong growth, especially with China’s rising demand for clean energy,” said Rohit Ghosh, Business Management Construction, Asia Pacific. “The milestone project is another successful collaboration between Harvest, one of China’s largest cryogenic insulation systems service providers, and BASF.”

In 2019, BASF and Harvest signed a strategic collaboration agreement to develop polyurethane (PU) insulation solutions for China’s cryogenic and shipbuilding industries. The agreement included using BASF products (Elastopir, Elastopor, Elastospray, Elastocoat) that are suitable for cryogenic applications, in LNG(-164℃)/ LEG/LPG ship‘s cargo tank, fuel tank & pipeline, offshore projects, and LNG terminal projects.

“Harvest has always focused on the cryogenic insulation industry, involving system solutions on product R&D, manufacturing, and installation, and has achieved excellent references. Harvest continues to work with BASF to provide better products and services for domestic and overseas customers,” said Zhengfeng Cheng, Chairman, Harvest.

The VLEC, designed and constructed by Jiangnan shipyard, is the largest globally and the first boat in the series. With its ship length of 230m and total volume of 99,000m3, it can load LEG (-104℃), LPG (-40℃), and other cryogenic liquid cargo. The dual-fuel primary engine power system can burn ethane and meets environmental protection emission requirements that will take effect in 2030.

Subscribe to our newsletter & stay updated.