BASF has strengthened its portfolio of Industrial and Transportation applications, with the introduction of an optimized Red Phosphorus polyamide grade for the Asian markets. Compared to conventional materials, the new Red Phosphorus grade is currently the best-in-class material due to its excellent mechanical performance and high flame-retardancy, with a PH3 release value of less than 20ppm.

“The launch of the new grade is significant on many fronts. It strengthens our flame retardant product portfolio for the Industrial and Transportation segments and fulfills technical requirements of electric mobility especially battery and power electronics. It also reduces lead times as it is now developed and produced in Asia for Asia,” said Desmond Long, Vice President, Transportation Industry, Performance Materials Asia Pacific, BASF.

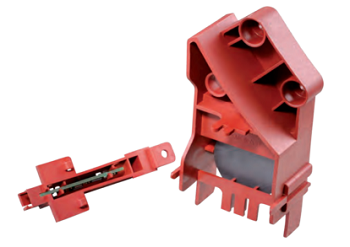

In Asia, the red phosphorus range of products is particularly in demand for applications related to electrification and power distribution. Examples of Industrial applications include switchgears, contactors, relays, and embedded poles. When used in the transportation segment, the grade is a cost-competitive material for electric vehicles’ battery modules, which requires flame retardancy.

The wider processing parameter of the innovative material enables more sustainable production owing to the efficient use of resources. The reinforced thermoplastic polyamide is also more sustainable than conventional materials as it can be reused – as opposed to insulating materials made of thermoset, which cannot be recycled. The optimized grade has demonstrated excellent phosphorus stability, and hence stands out among similar materials in its class.

The new Red Phosphorus PA solution also possesses excellent mechanical properties, including high charpy (unnotched and notched) impact strength and tensile strength, good flowability, and improved processability. The excellent stabilization of Red Phosphorous FR further prevents mold deposit and corrosion, making this new polyamide grade best-in-class. The manufacturing process of thermoplastics with injection molding is also more efficient and cost-effective.

“The new grade broadens and complements our portfolio of Red Phosphorus grades from the Solvay polyamide integration. This enables us to offer our customers innovative solutions for the booming power electronics market,” said Marilyn Lye, Vice President, Industrial Industry, Performance Materials Asia Pacific, BASF.

With the acquisition of the Solvay polyamide business, BASF now has its first UL certified lab in Asia. This UL certified testing capability significantly shortens the verification process, and thus the time-to-market of flame-retardant products such as the new Red Phosphorus polyamide grade. The new lab, located in Shanghai, is part of the company’s comprehensive global R&D network and complements BASF’s existing polyamide testing service for flame-retardant grades, mainly for electronic and electrical solutions.