Chemical

Chemetry partners with Zeton to build EDC demonstration plant

Once complete, the modular plant will be packaged and shipped to Braskem’s Vinyls site at Maceio, Alagoas State, Brazil.

-

By ICN Bureau | September 13, 2020

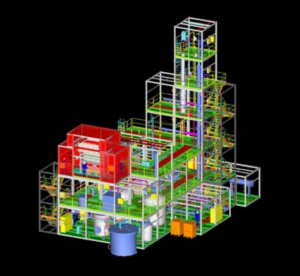

Zeton Inc. has been selected by Chemetry Corp. to provide detailed engineering, procurement, fabrication and factory testing of a modular demonstration plant based on Chemetry’s technology to produce Ethylene Dichloride (EDC). Zeton and Chemetry have designed the 1000 metric ton/year demonstration plant to prove the reliability and commercial viability of Chemetry’s eShuttle process. eShuttle was among the honorees for the 2017 Kirkpatrick Chemical Engineering Achievement Award.

The project is being designed and built at Zeton’s facility. Once complete, the modular plant will be packaged and shipped to Braskem’s Vinyls site at Maceio, Alagoas State, Brazil. After reassembly, the plant will be prepared for operation and commissioned by Braskem and Chemetry with assistance from Zeton. The plant will be in operation for approximately one year to adequately demonstrate the performance and reliability of the new process.

Zeton was chosen by Chemetry for their world class know-how and capability to design and fabricate scale-specific production plants on time and on budget. Zeton’s facility is designed to build small scale plants in modular fashion and perform factory acceptance testing of the integrated plant on its site in Ontario before disassembling the plant and shipping it to the final installation location. This capability results in smoother, expedited commissioning at the site.

Chemetry’s eShuttle EDC Process produces EDC, Hydrogen and Caustic Soda from Ethylene, Water, Sodium Chloride salt and Electricity using 25 to 50% less power than the current industrial processes. The eShuttle\ process does not produce chlorine gas, reducing the process safety risk when compared to other chloralkali processes. EDC is the primary raw material for PVC resins, widely used in construction and infrastructure projects around the world. Reducing the power consumption is an effective way to improve the sustainability and reduce the carbon footprint of this chemical process. The reduced power consumption also allows producers in higher power cost regions of the world compete more effectively with producers in low power cost regions. Last year, Chemetry announced its collaboration with TechnipFMC on a second proprietary process technology for propylene oxide.

Chemetry CEO, Ryan Gilliam: “As we looked at possible partners for the demo plant, Zeton, kept rising to the top based on their reputation for high quality, innovative design and cost effectiveness. We are excited to be working with Zeton as we make this critical step in commercializing our eShuttle EDC Process.”

Zeton CEO, Leisl Dukhedin-Lalla: “The Chemetry team have been an absolute pleasure to work with, and continually demonstrate their outstanding technical talent as they advance this technology. Zeton is honored to be selected as the preferred partner by Chemetry to assist them with scaling up their eShuttle process and we look forward to supporting the Chemetry team as they commercialize the technology.”