Dürr and GROB have been collaborating since 2022 to advance production technology for lithium-ion batteries

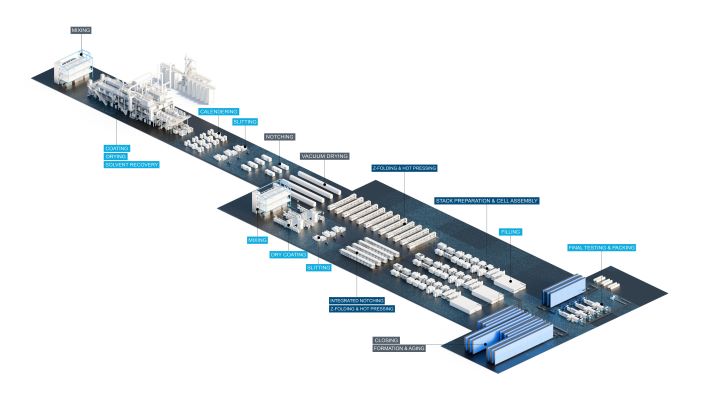

Engineering leaders Dürr and GROB have introduced a groundbreaking concept factory for lithium-ion battery cell production, designed to deliver top-tier performance, superior quality, and significantly lower energy and space requirements. At The Battery Show India 2025 in Greater Noida, the two partners are showcasing innovative technologies including dry electrode coating and high-speed Z-folder cell assembly with integrated notching.

Dürr and GROB have been collaborating since 2022 to advance production technology for lithium-ion batteries. Their joint mission is to establish themselves as leading system suppliers of battery production equipment across Europe, North America, and India. By localizing advanced technologies and fostering partnerships with Indian battery manufacturers, the companies aim to strengthen India’s self-reliant battery ecosystem in support of the national Atmanirbhar Bharat initiative.

“We are driving India's clean mobility transition with world-class manufacturing systems for lithium-ion batteries that combine global engineering excellence with local manufacturing and service support throughout the entire project and product life cycle,” said Aji Philip, Head of LiB at Dürr India.

German Wankmiller, CEO of the GROB Group, added, “With our expanded portfolio of high-performance machines and systems, we now cover almost the entire value chain for battery cell production using our own technologies.”

The concept factory combines Dürr’s dry coating and GROB’s Z-folder technologies, representing a major leap forward in battery manufacturing. This innovative approach reduces production space by 50 per cent and energy consumption by 70 per cent, while improving overall efficiency and reducing operating costs.

Dürr’s X.Cellify DC dry coating system implements the Activated Dry Electrode process developed with LiCAP Technologies. Instead of using a liquid slurry, it employs a dry-mixed powder that is pressed into a free-standing film and laminated onto both sides of a collector foil. This process eliminates the need for drying, solvent recovery, and treatment, resulting in significant savings in energy, space, and cost.

The free-standing film enhances material efficiency, as excess material can be completely recycled into the production process. The successful proof of concept demonstrates high and consistent quality, with Dürr now seeking pilot partners for industrial-scale implementation.

GROB’s new-generation Z-folder integrates the notching process and achieves high performance in a compact footprint. With minimal deflection rollers and low web tension, the system ensures stability and reliability. Its advanced magazine buffer for electrodes achieves 95 per cent system availability.

Dürr has developed a high-pressure electrolyte filling process that fills battery cells in a single step without residual gas. Operating at up to 30 bar—two to three times the industry standard—this process enables precise dosing, faster filling, and improved electrolyte penetration into the active material.

Dürr and GROB’s equipment solutions are enhanced by comprehensive digital integration. A digital twin enables complete simulation of the factory during the planning phase, speeding up implementation and ensuring smooth operation. This data integrates with Dürr subsidiary iTAC’s MES/MOM software for full production control, traceability, and quality management—resulting in higher overall equipment effectiveness.

For customers utilizing traditional wet coating methods, Dürr offers turnkey electrode manufacturing solutions including coating, drying, solvent recovery, distillation, and calendering. The X.Cellify SC series enables simultaneous two-sided coating using a straight-path flow and non-contact drying, reducing footprint and eliminating edge curl.

Dürr’s condenser and concentrator system achieves emission levels below 1 mg NMP/Nm³, setting industry benchmarks for environmental performance. Its high-precision calendering machines use Dynamic Gap Control technology to ensure uniform layer thickness and optimal compression for both wet and dry coatings.

Subscribe to our newsletter & stay updated.