Idaho National Laboratory (INL) is working with Minnesota-based Xcel Energy on a system to use a nuclear plant’s steam and electricity to split water.

The U.S. Department of Energy announced more than $10 million in funding for the project on Oct. 8. The project announced last week is part of the Energy Department’s strategy to reduce U.S. greenhouse gas emissions using nuclear power to generate carbon-free energy. Vehicles using hydrogen fuel cells, for example, produce only water vapor and warm air as exhaust. Hydrogen could also be used in industry, such as in the production of steel.

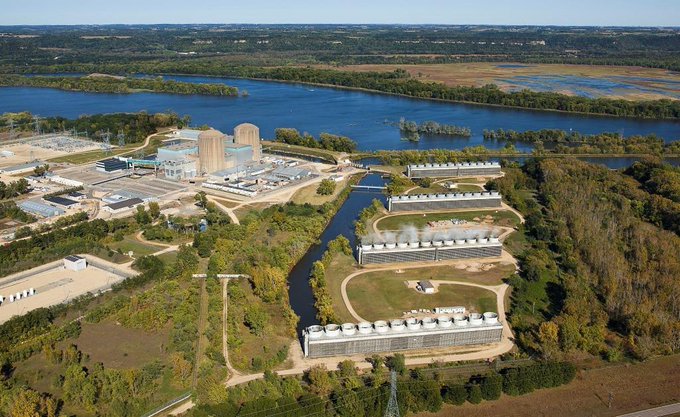

Idaho National Laboratory and Minneapolis-based Xcel Energy will work on devising and building the facility, most likely at Xcel Energy’s Prairie Island Nuclear Generating Station in Red Wing, Minnesota.

Xcel Energy officials said they have a large amount of wind-generated energy they supply to customers. Officials said the Prairie Island Nuclear Generating Station could make hydrogen when wind energy meets customer demand for electricity. Officials said the hydrogen would initially be used at the power plant but could ultimately be sold to other industries.

“Now we’ll be the first company to produce carbon-free hydrogen at a nuclear plant using this technology,” said Tim O’Connor, Xcel Energy chief generation officer.

The effort planned at the Minnesota plant will use a process called high-temperature steam electrolysis. Water is made out of three atoms: one oxygen and two hydrogen. The proposed project would use Prairie Island Nuclear Generating Station’s steam and electricity to split water and separate the hydrogen. Idaho National Laboratory will help with technical aspects of the project.

The Energy Department said it hopes the result will be a functioning hydrogen plant capable of operating as a hybrid system that can also test electrolysis technologies.

“This is a game-changer for both nuclear energy and carbon-free hydrogen production for numerous industries,” said the Energy Department’s Richard Boardman in a statement. “It offers a view of the energy structures of the future, which will integrate systems to maximize energy use, generator profitability and grid reliability all while minimizing carbon emissions.”

Hydrogen is abundant in the environment and is stored in water, methane and organic matter. The primary challenge is economically extracting it and being competitive in the marketplace. Most of the hydrogen currently produced in the nation comes from combining high-temperature steam with natural gas.

Today, industrial-grade hydrogen is produced by stripping it from natural gas molecules, emitting carbon monoxide in the process. Since nuclear power plants do not emit carbon or other air pollutants, hydrogen made by splitting water there will, it is hoped, lower the carbon footprint of industrial hydrogen customers.

“Today, a number of nuclear power plants could produce cost-competitive hydrogen — and, with additional electrolyzer (research and development) and more installations, many more nuclear plants could in the future,” said Mark Ruth, a group manager with National Renewable Energy Laboratory’s Strategic Energy Analysis Center and lead author of a report analyzing the potential cost-competitiveness of producing hydrogen at nuclear plants.

Commercial hydrogen production via low-temperature electrolysis will be demonstrated by a previously awarded project launched in September 2019. Led by Energy Harbor’s Davis-Besse Nuclear Plant near Toledo, Ohio, the two-year project will demonstrate a low-temperature electrolysis unit to produce commercial quantities of hydrogen. The third utility taking part in the project, Arizona Public Service, which operates the Palo Verde Generating Station, is also evaluating the integration of nuclear energy with hydrogen production.

“Holistic integration of the energy system will involve contributions from electrical, thermal and chemical networks, as well as greater utilization of energy storage at various scales,” Boardman said. “That’s how the commercial nuclear power industry can provide reliable, sustainable, low-emission and affordable energy and energy products to its customers.”