This project enables the first production of Škoda vehicles in Vietnam, supporting the brand's entry into the country and regional expansion

Dürr has successfully completed a turnkey paint shop project for Thanh Cong Group (TC Group) at the new Thanh Cong Viet Hung (TCVH) automobile factory in Quang Ninh, Vietnam, which is 100% invested by TC Group.

The TCVH plant represents a major step forward in the Vietnamese government’s vision to establish a large-scale, modern automotive industrial complex in Quang Ninh.

TC Motors has made significant investments in infrastructure, logistics, and supporting facilities to expand European car manufacturing in Vietnam.

The factory covers an impressive 36.5 hectares and boasts an annual production capacity up to 120,000 vehicles.

The new facility is set to become a central hub for Škoda vehicle distribution across Southeast Asia and contributes to local economic development through job creation, increased tax revenues, and the training of skilled professionals.

Located in Quang Ninh, Vietnam, the TCVH automobile factory is dedicated to producing the first Škoda automobile models in the country, including the Škoda Kushaq and Škoda Slavia. Moreover, the plant’s strategic location near Haiphong port ensures efficient logistics for importing completely knocked down (CKD) kits from Pune, India. Phase I of the plant is de

Despite global supply chain interruptions through sheet metal processing and electrical components constraints, fluctuations in maritime transport, and extreme weather events like Super Typhoon, Dürr completed the project within 18 months. From contract signing in November 2023 to final acceptance in July 2025, the project was delivered on time and to specifications.

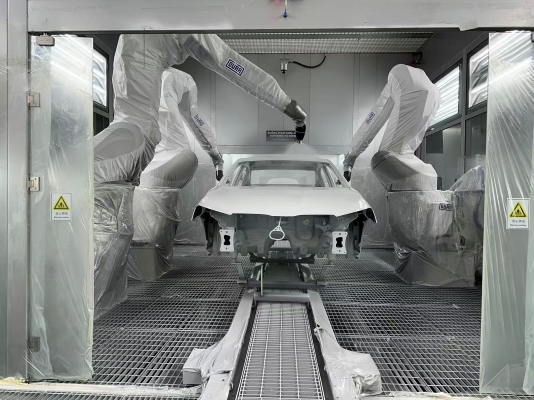

Dürr played a key role in equipping the paint shop with advanced technology. The highlight is the electrically driven RoDip E for pretreatment and electrocoating, using freely programmable trolleys. Each trolley has a conveying drive and a rotating drive, which enable horizontal and rotating movements to be controlled independently of each other for each body.

Subscribe to our newsletter & stay updated.