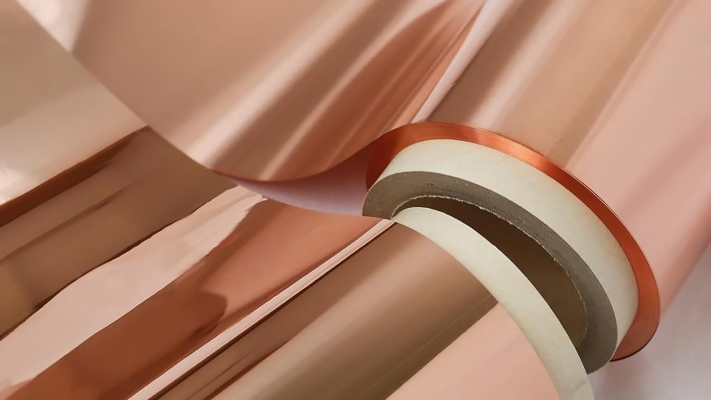

New Gardolene D passivation solution provides superior corrosion protection and improves battery performance

New Gardolene D passivation solution provides superior corrosion protection and improves battery performance. Photo: BASF

Chemetall, the global surface treatment business unit of BASF Coatings and a leading provider of innovative surface treatment solutions, introduces the first chromium-free and fluoride-free passivation technology for copper foils, Gardolene D.

This pioneering solution is unique in the industry and offers superior corrosion protection as well as improved performance of copper foils used in electric vehicle battery packs, energy generation and storage systems.

The new Gardolene D technology sets a new benchmark for sustainability and performance while also offering long-term regulatory compliance in copper foil treatment for the battery manufacturing market.

The world has seen an increasing demand for high-performance batteries in electric vehicles (NEV), consumer electronics (3C), and energy storage systems (ESS) over recent years. The new Chemetall Gardolene D passivation solution for copper foils enhances battery performance, is more sustainable, and is fully compliant with the European Union’s new Battery Regulation (EU 2023/1542), which mandates carbon footprint declarations, digital battery passports, and strict limits on hazardous substances.

From 2027, only batteries meeting these standards will be allowed on the European market, driving the need for green manufacturing and chromium-free pretreatment technologies.

“The green transformation, with continuously rising electric vehicle numbers and an increasing market for new concepts in energy generation and storage systems, needs new, innovative surface treatment solutions. At Chemetall, we are committed to solving our customers' challenges and supporting their business with our expertise. The new Gardolene D passivation solution for copper foil ushers in a new era for copper foil passivation, with increased battery performance, greater sustainability, and future-proof customer processes. It is another great example of what our claim ‘expect more’ means for us: providing innovative solutions in the metal-using industry that offer added value to customers,” says Frank Naber, Senior Vice President Global Surface Treatment at BASF Coatings.

“The new Gardolene D passivation solutions for copper foil are a pioneering innovation for the market. Our dedicated research and technology teams across the globe have intensively analyzed available solutions and market needs. Based on our comprehensive expertise in surface treatment and close exchange with our customers, we were able to push boundaries and develop this one-of-a-kind global solution for copper foil pretreatment. It ensures stable copper foil properties, improved electrode conductivity, and supports manufacturers in meeting evolving regulatory and sustainability requirements compared to standard passivation processes,” says Arjan Termaten, Head of Global Technology at Chemetall.

Subscribe to our newsletter & stay updated.