The facility is a 50:50 joint venture and involved a mid-double digit million Euro investmen

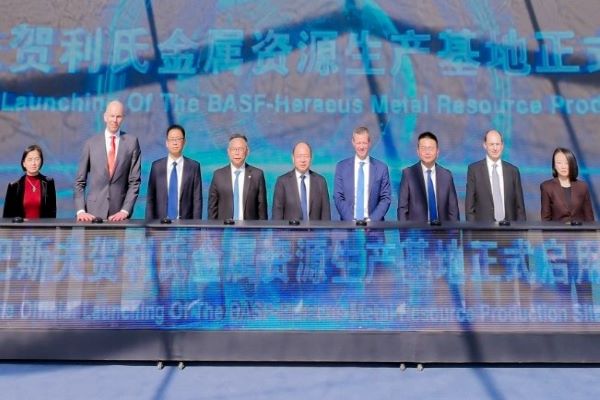

BASF Environmental Catalyst and Metal Solutions (ECMS) and Heraeus Precious Metals have commenced operations of a new joint venture facility, BASF Heraeus Metal Resource (BHMR) located in Pinghu, China. The facility recovers precious metals from spent automotive catalysts, enabling a circular economy, while supporting China’s security of supply and sustainability goals.

The facility is a 50:50 joint venture between the two industrial leaders and involved a mid-double digit million Euro investment. Construction was completed in 16 months. On an area of 32,000 square meters and with over 100 employees, BHMR has a recycling capacity of approximately 10,000 tons of autocatalysts annually. The commencing of operations comes at a crucial juncture with the earliest PGM-carrying automobiles enter the recycling phase.

“The joint venture will utilize ECMS's pyrometallurgy recycling technology, providing customers with state-of-the-art technology for the recovery of precious metals,” said Tim Ingle, Senior Vice President, Precious Metal Services and Recycling, ECMS. “China is an important market for ECMS as one of the largest consumers of precious metals and BHMR will facilitate the reuse of precious metals in China, supporting circularity and enabling our customers to reduce their CO2 footprint.”

China relies heavily on imported precious metals due to limited domestic supplies. This highlights the importance of recycling to meet the country's needs, particularly for essential metals like platinum, palladium and rhodium, which are utilized in various industries such as petrochemicals, pharmaceuticals and automobiles.

According to market research, the Chinese autocatalyst recycling market is expected to experience remarkable growth, with an estimated annual growth rate of 18%. Hu Min, Head of Heraeus Precious Metals China, explained "The establishment of the joint venture will not only help our customers to buy their precious metals from a sustainable and traceable source, but also contribute a stable supply for China's precious metals supply chain."

Recycling precious metals offers a substantial reduction in carbon footprint, potentially saving up to 98% of carbon emissions compared to mining operations. “Our investment in the joint venture is part of a global €300 million recycling expansion program spanning China, the USA and Germany,” emphasized Marius Vigener, Senior Vice President Business Line Chemicals at Heraeus Precious Metals. “It will support our customers by meeting their increasing demand for low carbon footprint products. This commitment to sustainable development benefits not only both companies but also the wider PGM and downstream industries.”

“The inception of BHMR represents a pivotal moment, not only for ECMS and Heraeus Precious Metals, but for the broader context of China's industrial and environmental roadmap, as it intends to enhance both the supply chain and ecological footprints within the industry,” said Nancy (Ying) Ren, General Manager of BASF HERAEUS Metal Resource. “We extend our deepest gratitude to the joint BHMR project team, our partners in the construction company, and local authorities. It is the commitment of all those involved that ensured the project's rapid and successful completion ahead of schedule.”

Subscribe to our newsletter & stay updated.